Concepts

Sewing, setup, and finishing of overlock hemming is made easier, higher quality, and less expensive.

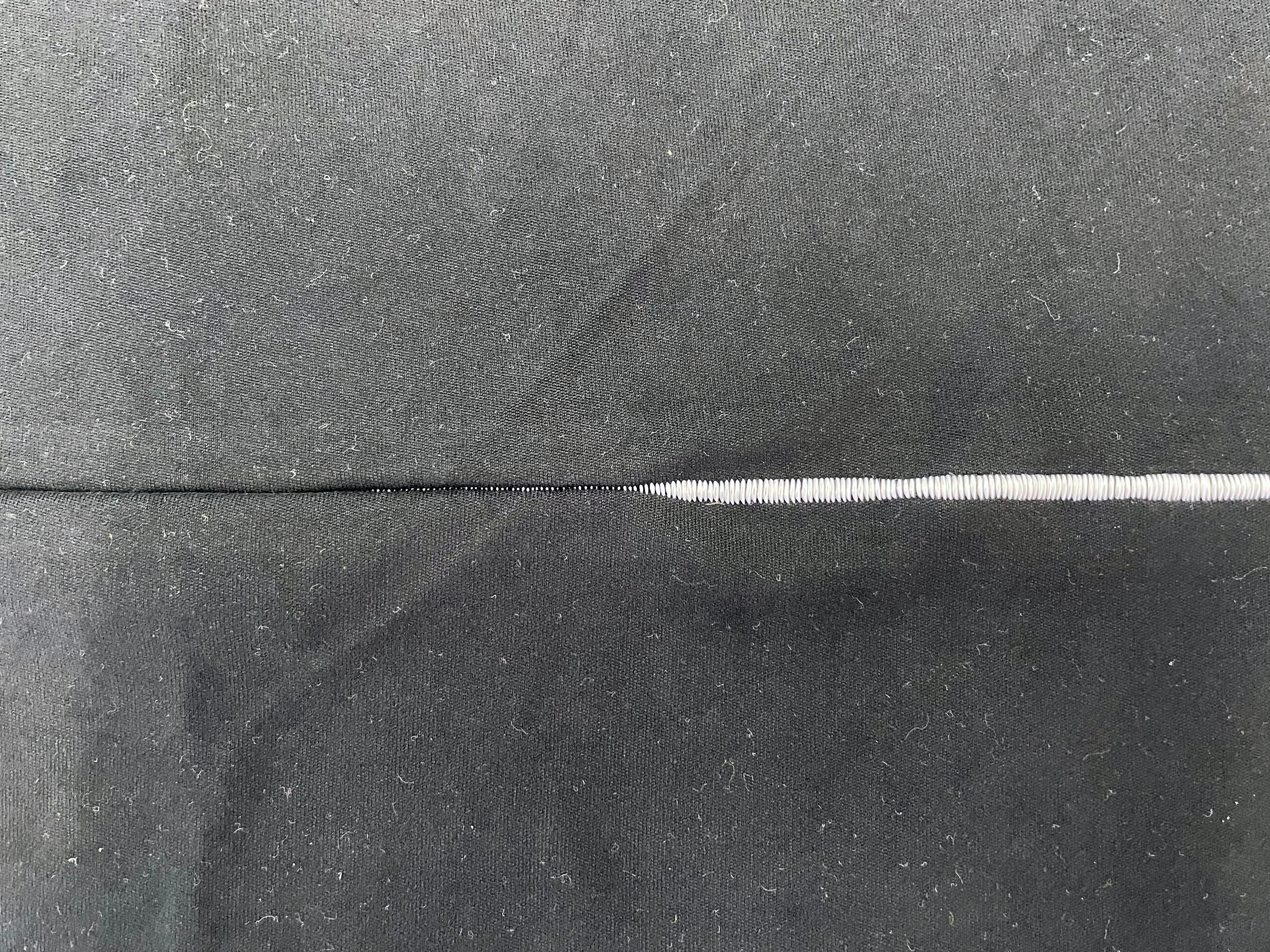

Demand for overlock hemming is increasing due to its high elasticity and designability, but it is also a difficult process that requires high skills, such as the need to form and hold hems in an S-shape, and it is difficult to mass-produce stable quality without skilled operators.

Yamato offers a range of de-skilling and labor-saving equipment for overlock hemming that enables even beginners to sew quickly and with high quality, and dramatically improves productivity and quality in a short period of time.

Highlight

Easy overlock hemming

Automated workstations realize stable quality and efficiency at the same time

High-speed & Labor-saving Seam Opening Operation

Further productivity improvement through mechanization of back-end process

Feature

Yamato's Overlock Hemming Solution

Easier and more beautiful hemming by overlock machine

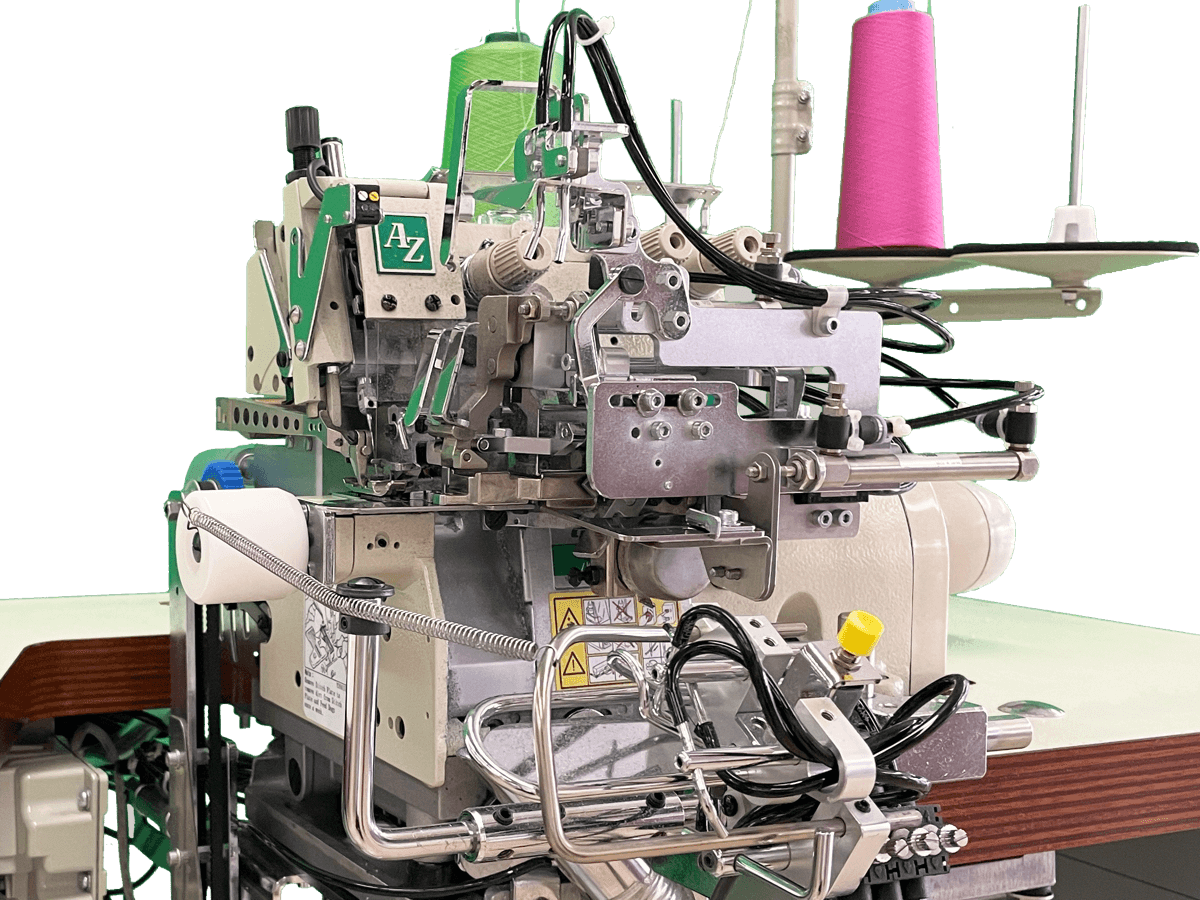

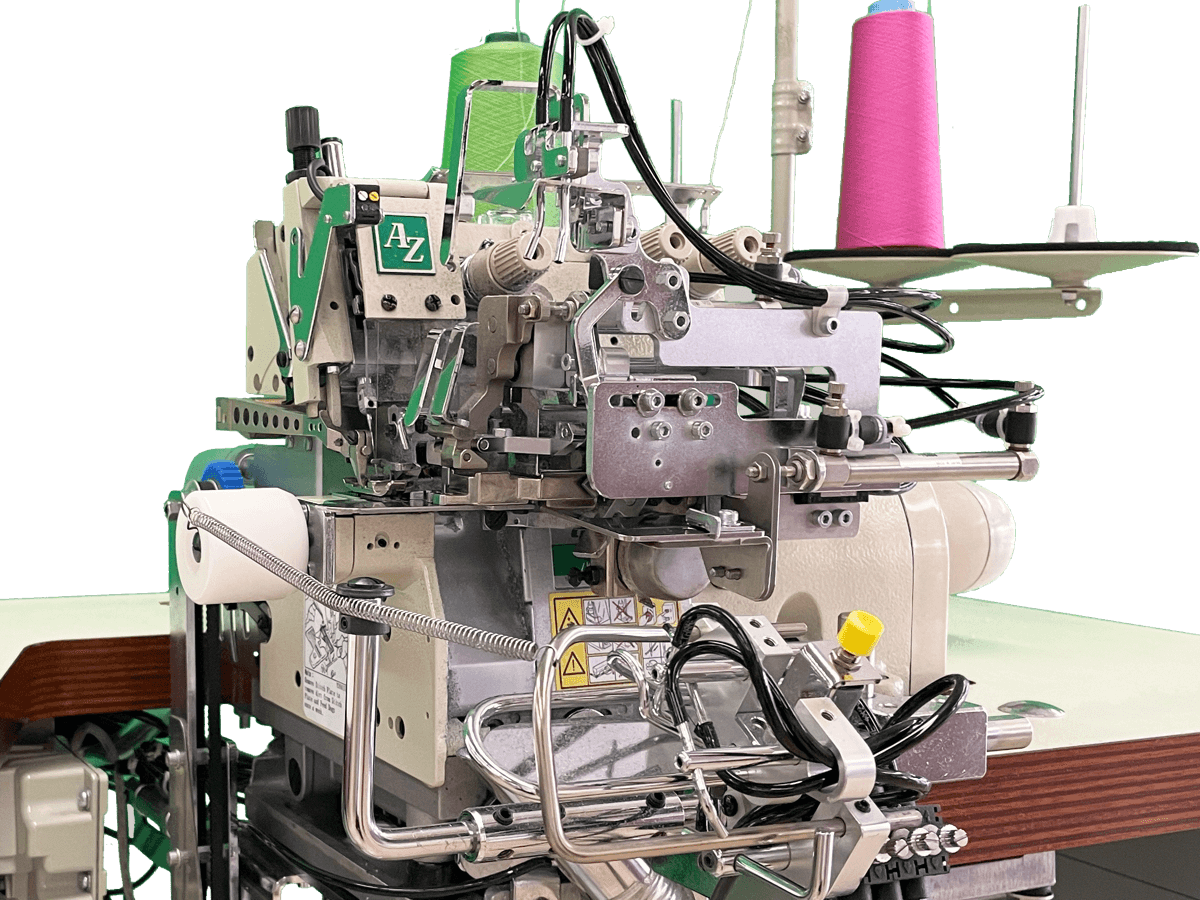

ABH-500 Semi-Automatic Easy Overlock Hemming Workstation

No difficult operation is required to form hems in an S-shape and keep holding them , and anyone can perform homogeneous sewing by simply setting fabric on the device.

The machine is easy to operate and stable enough to finish even in stepped sections without blank stitch.

Stitch depth can also be adjusted with a single dial. This makes it easy to meet the requirements of each specification.

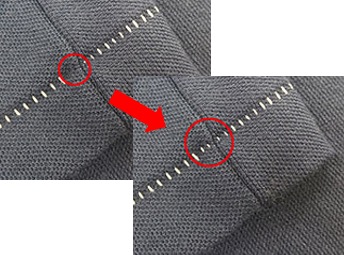

Minimizes quality risk even for beginners. Beautiful stitches without blank

Beautiful stitches without blank even in stepped sections.

Regardless of the operator's skill level, the hems are uniform in width and the seams are defect-free for high quality sewing.

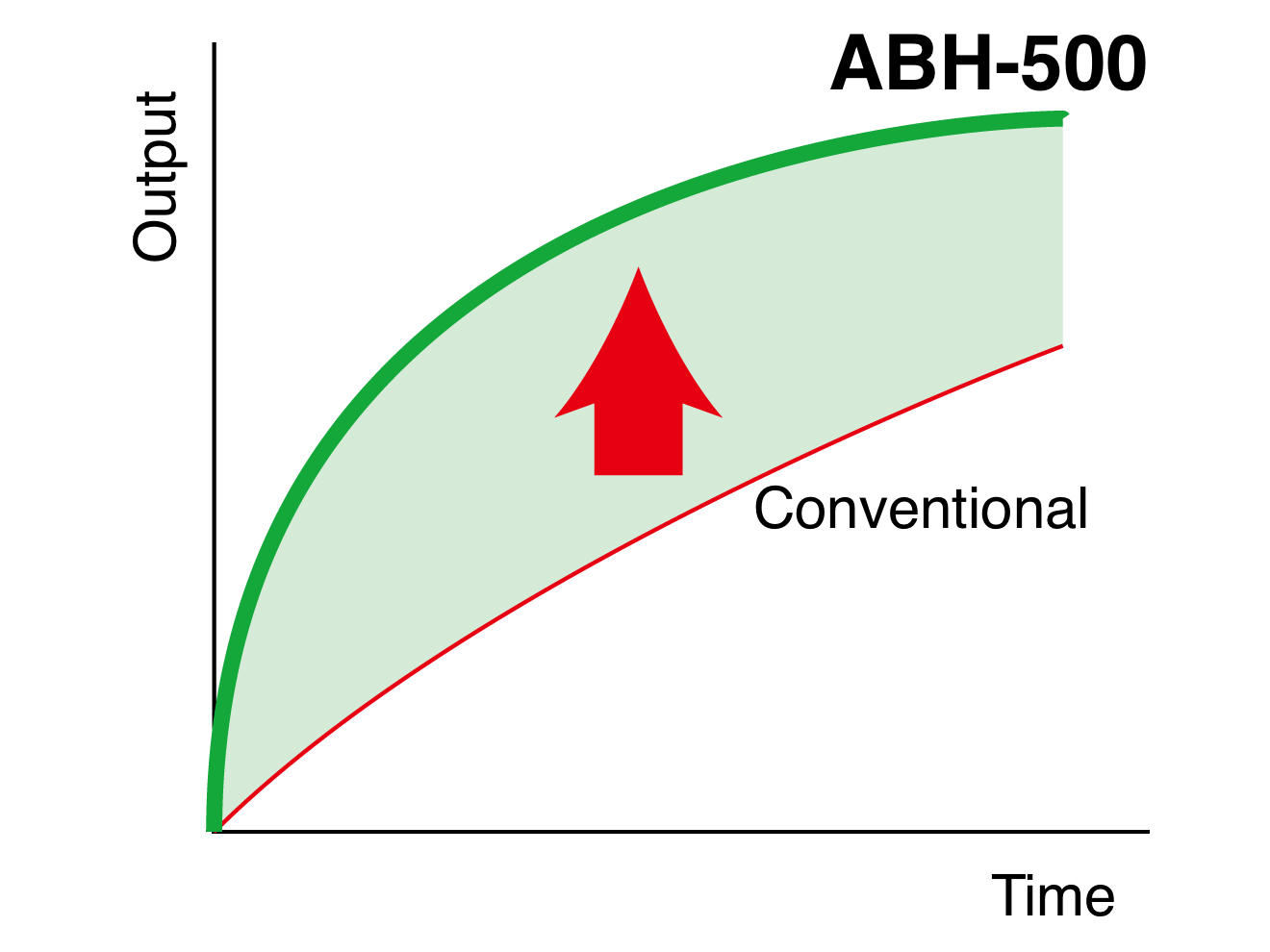

Stable production and vertical start-up without relying on skilled workers

The deskillizing performance of the ABH-500 allows even novice operators to mass produce high quality products in a few days. Vertical start-up is possible even without skilled operators, maximizing productivity in a short period of time.

Further production efficiency by mechanizing the post-processing as well

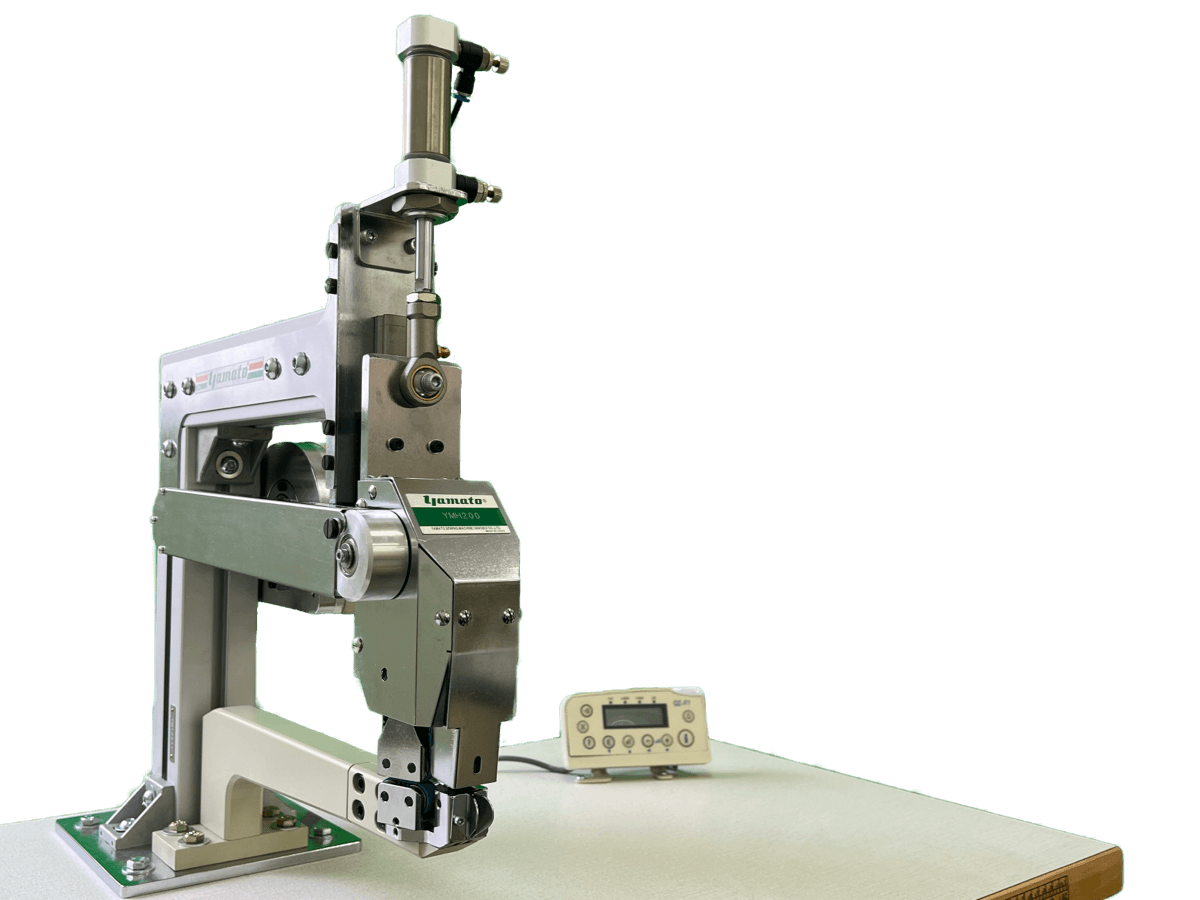

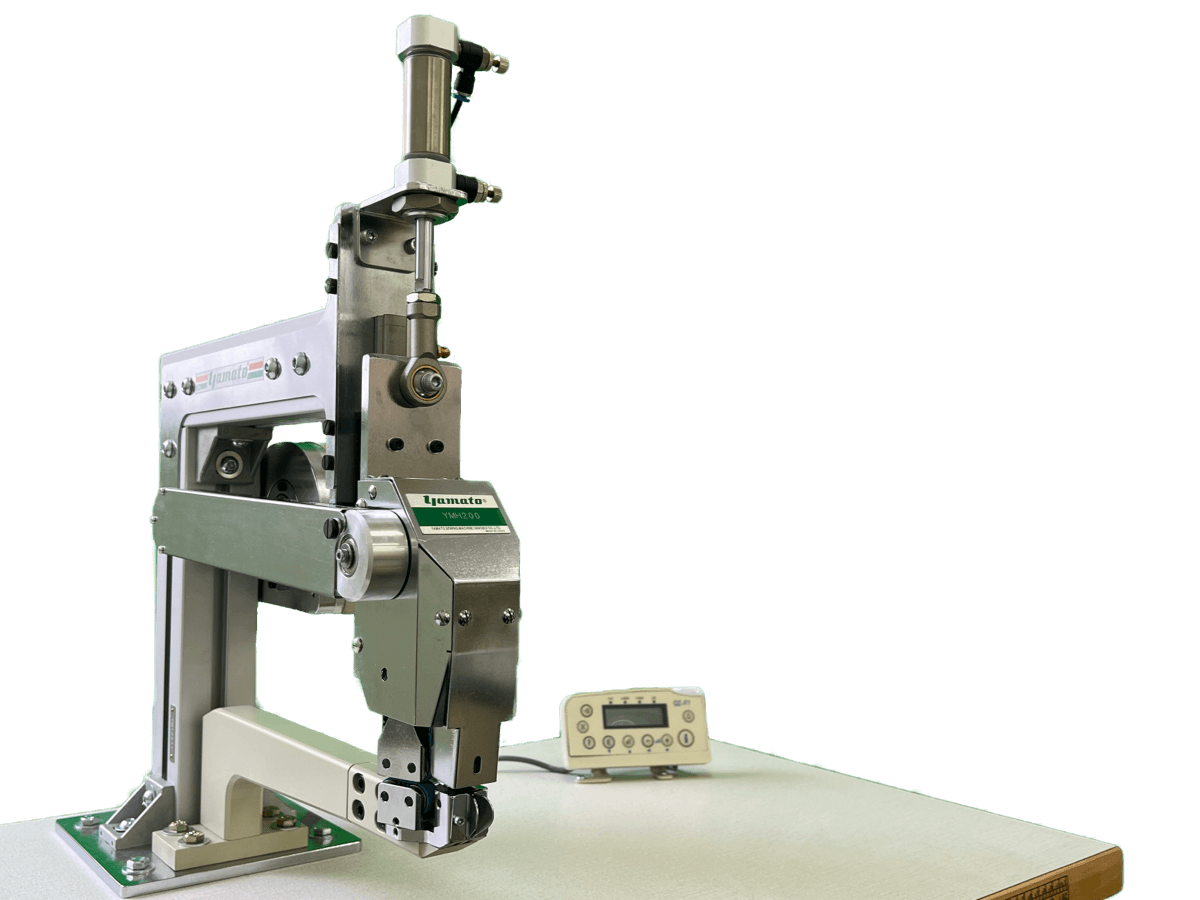

YMH-200 Seam opening machine

For the seam opening process after overlock sewing, the automatic seam opening machine YMH-200 can be introduced to speed up.

Compared to manual work, efficiency is improved by more than 50%, and quality risks such as finish variation and finger marks, which are unavoidable with manual work, are resolved.

When used in combination with ABH-500, it supports even more reliable high-speed production.

Product line-up

ABH-500

Semi-Automatic Easy Overlock Hemming Workstation

Semi-automates hemming of overlocking, which used to require a high level of skill. Stable production is realized without relying on skilled operators

YMH-200

Seam opening machine

Mechanize the seam opening process, improving efficiency by more than 50% compared to manual operation, and eliminating the risk of variation and staining caused by manual operation.

日本語

日本語  中文

中文