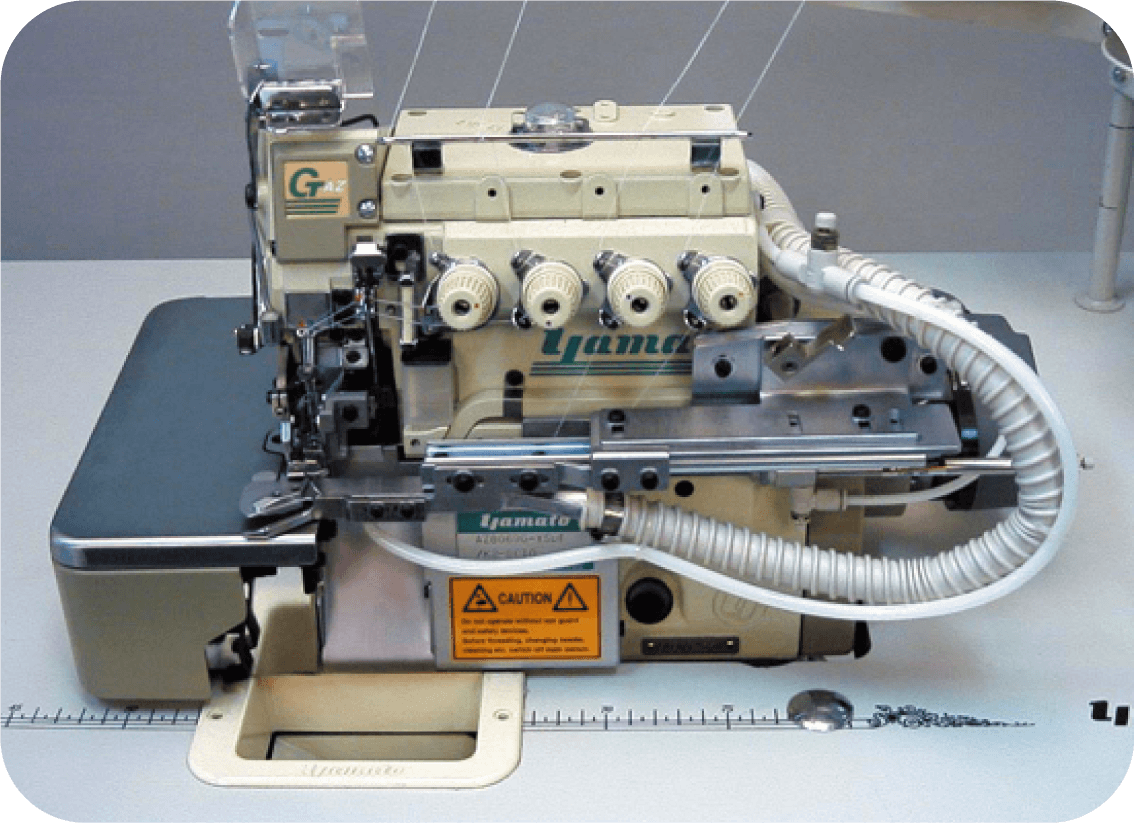

"Speed & Dry" Super High Speed Overlock & Safety Stitch MachineAZ8000SD-8 & AZ8500SD-8 class

Advanced Feed Mechanisms for Dealing Difficult Materials

Tapes, Thread and Thread-chain Cutters

Deskills Difficult Operations to Improve Quality and Productivity

TC/CH20

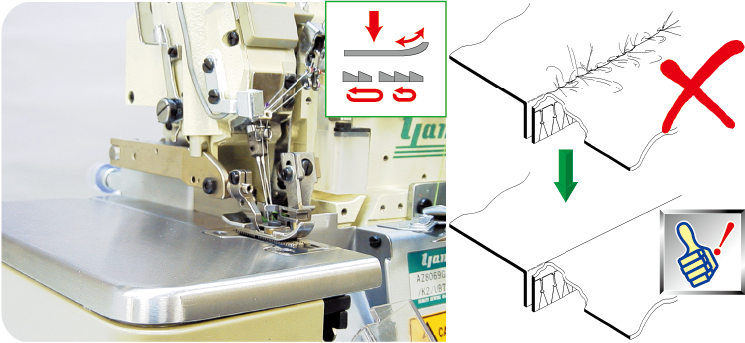

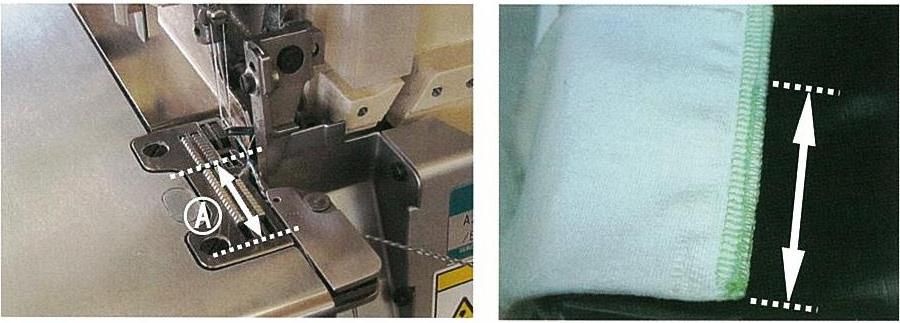

Blind Hemming Guide with Sideseam Sensor with Quick Change Thread Tension Controller for Blindstitch Hemming ⇆ General seaming

TC/CH20 is the Blind Hemming Guide Package which Prevents Misalignments During Blind Hemming Operations.

Plyshifting on the cross seam sections is a common cause of misalignments during the blind hemming operations.

This package detects the cross seam sections by its sensor and automatically slides the guide to prevent fabric misalignments. The guide slides back once reaching for the predetermined stitch count.

Just turning the TC lever, you may change thread tension as appropriate according to sewing applications such as blind hemming or general seaming.

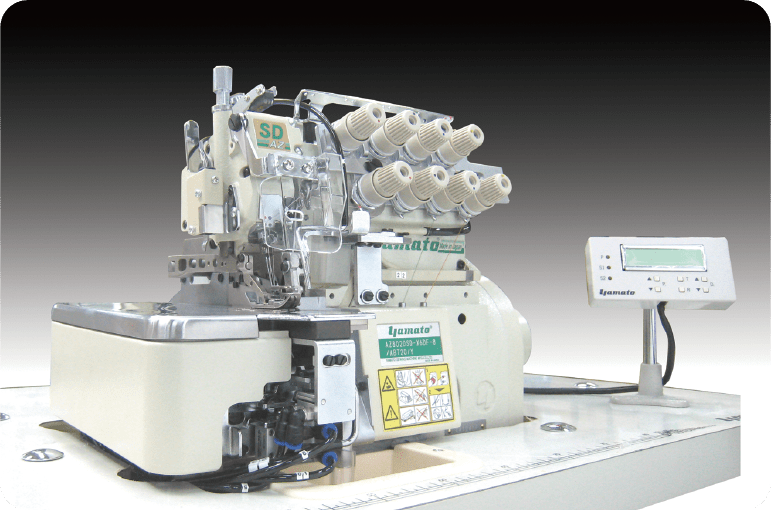

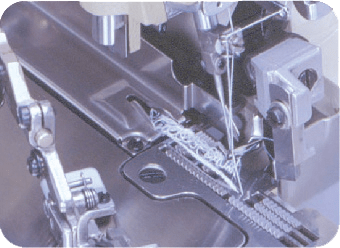

UB6

Suction Type Fabric Uncurler

A suction type fabric uncurler which suck the curling part of the fabric while guiding the fabric and prevent curls. UB6 minimizes fabric loss while enabling non-stop sewing. The device can slide away at the end of sewing to support certain overlapping. UB6 contributes to achieve uniform finishing size, minimizes fabric loss and improves productivity.

UB6 is applicable for AZ and AZF series machines.

Advanced Feed Mechanisms for Dealing Difficult Materials

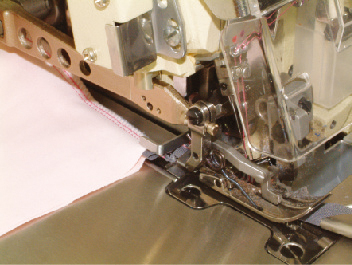

FF

Floating Pressor Foot

Designed to move back and forth in co-operation with minimum pressure and help positive feeding performance.

Floating Pressor Foot prevents puckering and slippage during sewing on a wide range for various kind and weight of materials. The Floating Pressor Foot also prevents fabric misalignment during the sleeve attaching process of the curved fabrics.

Applicable for: AZ8060, AZ8061, AZ8069 & AZ8560 overlock machines

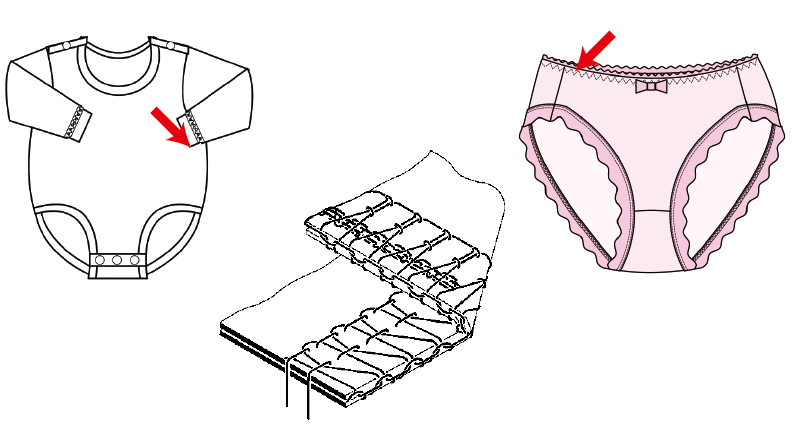

Anti-unraveling, Back-tacking and Condense-stitching

ABT20

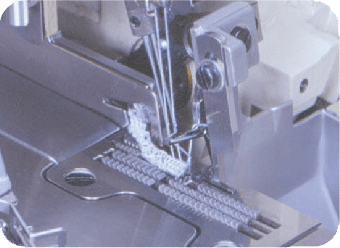

Automatic Back-tacker with Straight Chain Casting System

Clean-finish & Secure back-tack is made while you blink! ABT20 supports to reduce operators' fatigue, decrease defects & improve productivity

ABT20 enables real quick back-tack procedure for you to operate like usual overlock with chain cutter only.

As the thread chain is wrapped by the seam, without being interfered by needle threads, much less risk for failure is expected.

Nothing to disturb operator's sight for stress-free loading and handling of the work.

ABT20 is packaged with "self-cleaning system" to minimize downtime in cleaning and prevent the work from being stained. Also compact servo motor is already included!

Applicable for: Overlock machines

BT43

Back-tacker, Fitted with Needle Thread Tension Release System

Semi-automatic back-tacker suitable for a various kinds of knit wear sewing

Realizes neat and durable seams and soft thread chains suitable for back-tacking thanks to the movable stitch tongue in response to the fabric detection function and the needle thread tension release system.

Improved chain cutter shortened the length of thread chain into the seam so that back-tacking for shorter length seaming can be performed.

B3

Manual Back-tacker

Manual back-tacking device.

The thread chain will be sewn into the fabric at the beginning of sewing.

Tapes, Thread and Thread-chain Cutters

K1

Automatic Thread Chain Cutter (Horizontal Type)

Controlled by the compressor air, it sucks the thread chain and cuts them and collects the dust. The package saves your time, and gives you a clean working environment.

This horizontal type thread chain cutter is usually fitted with safety stitch machines and interlock machines.

To collect dusts, a separate venturi device is required.

K2

Automatic Thread Chain Cutter (Vertical Type)

Controlled by the compressor air, it sucks the thread chain and cuts them and collects the dust. The package saves your time, and gives you a clean working environment.

This vertical type thread chain cutter is usually fitted with overlock machines.

To collect dusts, a separate venturi device is required.

MT22

Solenoid Type Tape/Thread Chain Cutter

MT22 cuts reinforcing tapes, piping tapes and/or thick thread chains quickly and neatly at your desired point in sewing processes to improve productivity.

MU44 & MU45

MU44: Solenoid Type Automatic Tape/Thread Chain Cutter at Beginning and End of Sewing & MU45: Solenoid Type Automatic Tape/Thread Chain Cutter at Beginning and End of Sewing, with Thread Tension Releaser

MU44 & MU45 are Solenoid Type Automatic Tape & Thread Chain Cutter at the Beginning and the End of Sewing. In addition to MU44, MU45 equip the Thread Tension Releaser to make extremely soft thread chains, easy to be cut and hard to be unraveled.

Opetation

- After an operator sets a material and toe down the pedal, the MU device start functioning automatically and cuts the thread chain at the beginning and end of sewing.

- The fabric detection switch detects the front and rear edges of the material, and after the thread chain is cut, the cut thread chain is suck in suction pipe. Therefore, operation ef ciency is increased.

- By changing values on the control panel, length of a thread chain at the beginning and end of sewing can be changed.

- Air blows only at the beginning and end of sewing (by the air saving device), and even if the manual switch is pressed wrongly, the trimming device does not function during sewing (while the material is under the knife).

- MU45 device has a thread tension releaser. It makes good seam while sewing and makes a chain easily off after sewing.

Note : MU44 and MU45 need a compressor suctioning the cut thread chain.

Improve Operability and Maintainability

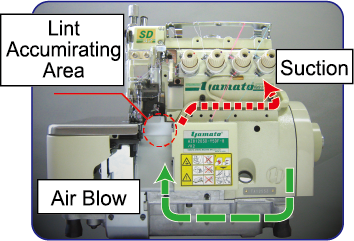

SC18

Self Cleaning System

Prevent oil stain by greasy dust

SC18 is the Self Cleaning System for overlock & safety stitch machines that prevents oil stain by greasy dust.

SC18 eliminates accumulating of dust around the lower knife and the area under stitch plate and ensures clean operation environment.

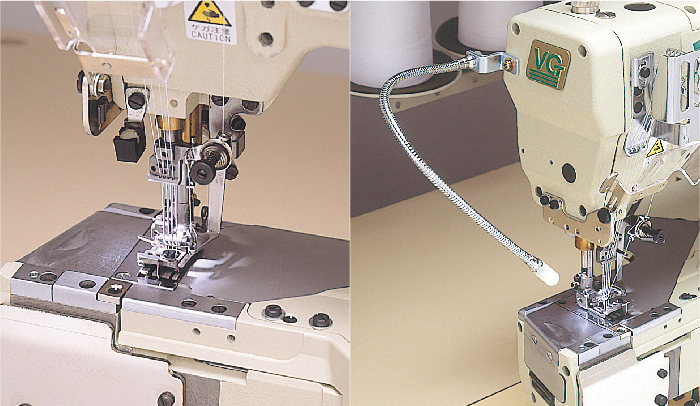

TL1 & TL2

Compact Spot Light

This heat-free, long life compact spot light lightens the needle dropping point and allows operators to see sewing area clearly. It is convenient when sewing, threading, changing needles and adjusting loopers and so on.

TL1: Fixed type Compact Spot Light

Suitable for threading

TL2: Flexible type Compact Spot Light

Also convenient for threading and adjustments)

Applicable for: All machines

TL devices is compatible 100V to 240V.

日本語

日本語  中文

中文