"Speed & Dry" Overlock & Safety Stitch MachineAZ7000SDR-8 & AZ7500SDR-8 class

Speed + Dry Finish Overlock & Safety Stitch Machines

- Yamato AZ7000SDR-8 & AZ7500SDR-8 series realize high productivity by high speed operation, high quality garment by stain-free dry finish and long lifetime machines, thanks to Yamato's signature "Speed + Dry" Technology (a.k.a. SD Technology).

- Yamato AZ7000SDR-8 & AZ7500SDR-8 series are the 3 in 1 overlock and safety stitch machine series that offers high speed, stain free dry finish and higher durability.

High Speed Operation

Yamato signature SD Technology guarantees high durability and high speed of 7,500 sti/min operation.

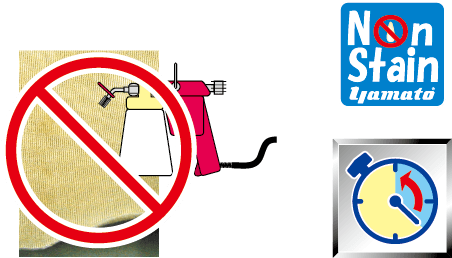

Prevent Oil Leakage for High Quality Garments

Prevent oil stains by circulated minimal liquid lubrication and the special sealing technology!

Long Lifetime Machine

High durability thanks to the efficient lubrication made by the unique oil circulation system and high-tech processed parts.

SPEED + DRY FINISH

IDEAL STITCH PERFORMANCE

EASE OF USE & EASY MAINTENANCE

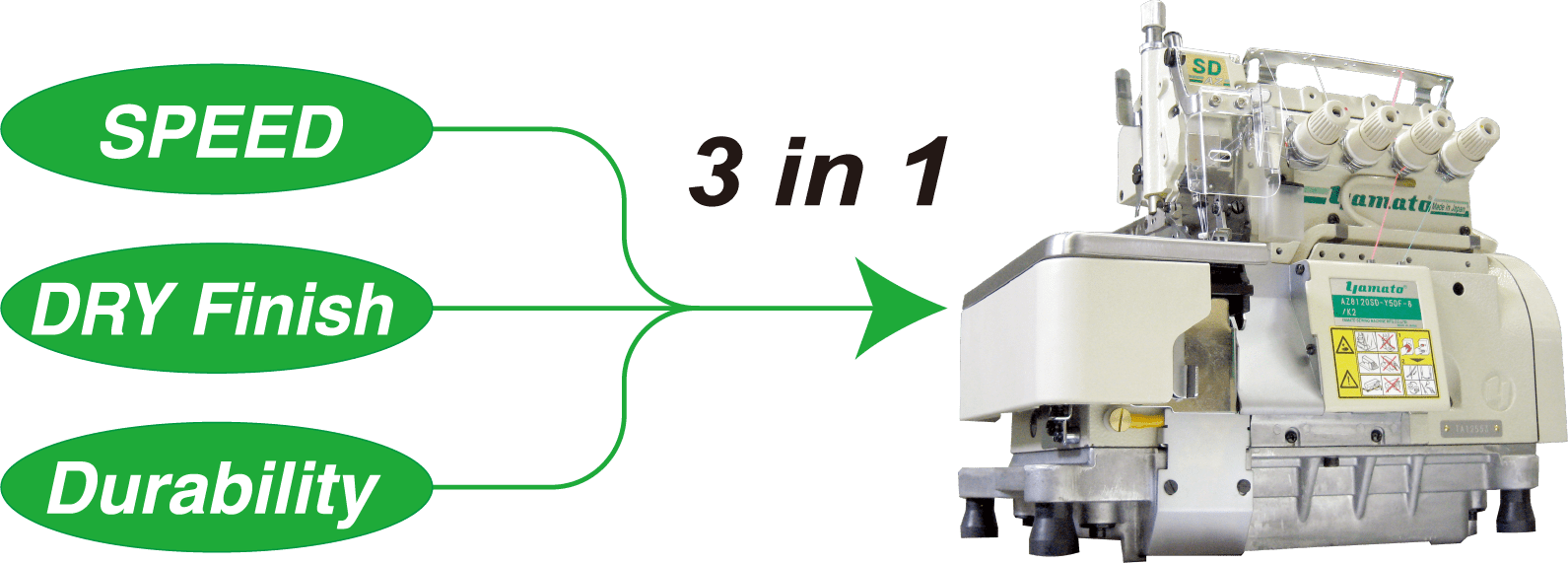

SPEED + DRY FINISH

The 3 in 1 Overlock & Safety Stitch Machines that Offers High Speed, Stain Free Dry Finish and Higher Durability.

Yamato AZ7000SDR-8 & AZ7500SDR-8 series realize high productivity by high speed operation, high quality garment by stain-free dry finish and long lifetime machines, thanks to Yamato's signature "Speed + Dry" Technology (a.k.a. SD Technology).

Yamato AZ7000SDR-8 & AZ7500SDR-8 series are the 3 in 1 overlock and safety stitch machine series that offers high speed, stain free dry finish and higher durability.

High-Speed and Durability are Guaranteed by the High-tech Processing and the Controlled Circulation.

High-tech processing parts which greatly reduce frictions as same as so-called "dry head" machines are introduced on the needle bar and the upper looper mechanism. A smooth driving is achieved by minimal liquid lubrication compared with the conventional models.

Moreover, high durability and high-speed of 7,500 sti/min are guaranteed because of an efficient lubrication made by the unique circulation system.

摩擦係数の比較

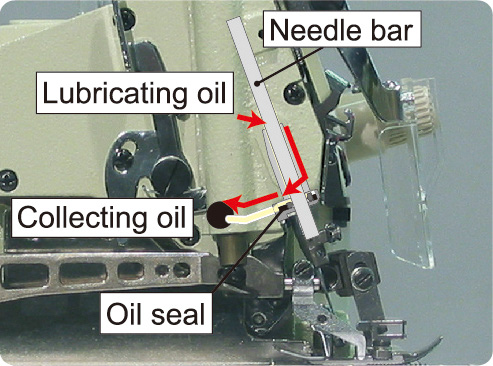

Prevent Stains by the Circulated Minimal Liquid Lubrication and the Special Sealing Technology!

Not only minimal lubrication but also the special sealing technology is introduced on the needle bar and the upper looper mechanism. While feed a steady small amount, oil is wiped away with the oil seal before the moving parts are exposed. The wiped oil is circulated and doesn't leak outside.

Upper looper

IDEAL STITCH PERFORMANCE

Ideal Stitch Performance

You can obtain neatly tightened and highly durable finish. Soft and elastic seam is also available as the stitch is formed without stress on each thread.

Needle Thread Take-up Mechanism Activated by Upper Knife

Looper thread take-up mechanism co-operating with looper timing produces straight and stretchable soft-chain with balanced stitch formation.

VERSATILITY

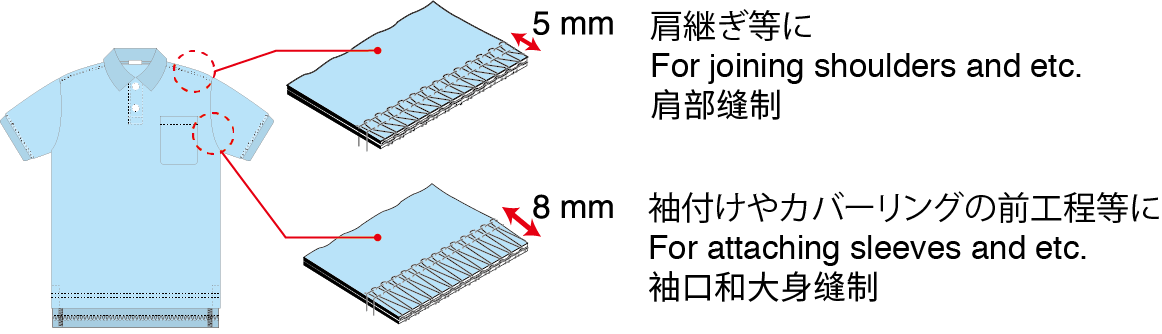

Versatility (AZ7120SDR-8)

Seam witdth from 5 mm to 8 mm is convertible by simple replacement of the stitch plate and the pressor foot tongue, without any adjustments.

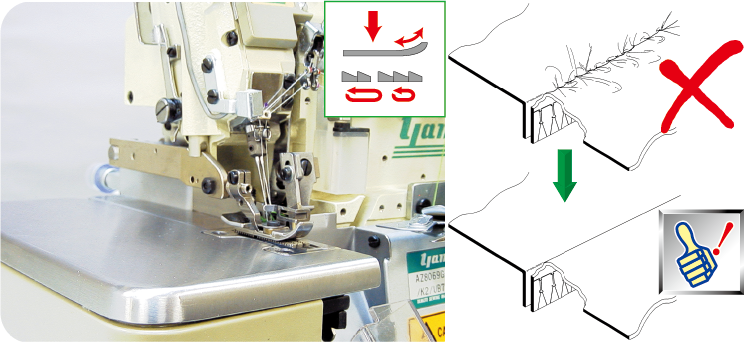

Floating Foot Compatibility

Designed to move back and forth in cooperation with feed dogs with minimum pressure.

Floating foot delivers neat flat finish preventing twisting and slippage during sewing on a wide range for various kind and weight of materials.

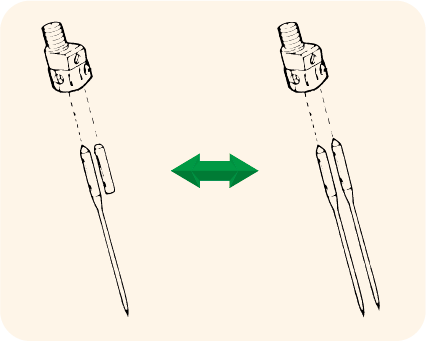

Equipping Needle Clamp for 2 Needle Specifications as Standard

Needle clamp for 2 needle specifications is equipped even on single needle model. Therefore, change-over from single needle use to 2 needle use can be easily provide.

EASE OF USE & EASY MAINTENANCE

Easy setup and maintenance

Feed dog angle adjustment

The feed dog tilt is easy to tilt up or down from outside of the machine depending on the sewing conditions.

Upper looper bar adjustment

Easier access to adjusting screw for less downtime in addressing different sewing conditions.

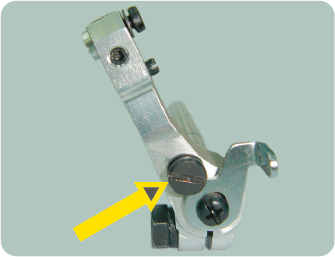

Lower looper holder adjustment

Easy adjustment of lower looper with the micro-adjuster.

SC18

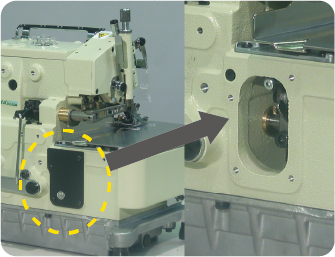

Self Cleaning System

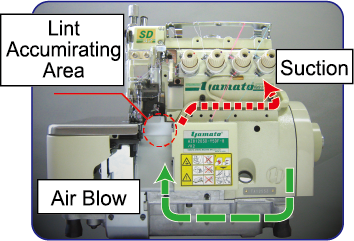

Prevent oil stain by greasy dust

SC18 is the Self Cleaning System for overlock & safety stitch machines that prevents oil stain by greasy dust.

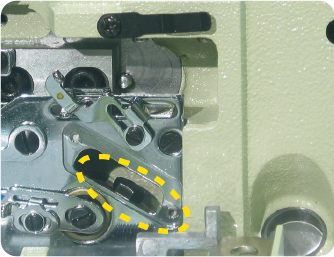

SC18 eliminates accumulating of dust around the lower knife and the area under stitch plate and ensures clean operation environment.

Easy to See Sewing Area

It is easy for operators to see the sewing area and this feature improves sewing performance.

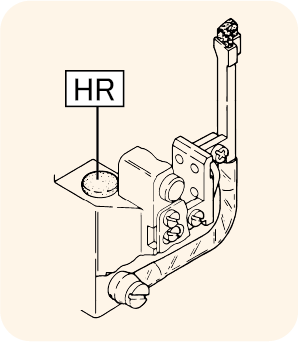

HR Needle Cooling Device is Now Built-in

Sealed compact design needle cooling device eliminates dust or alien substances, as the result it ensures constant cooling needle.

日本語

日本語  中文

中文