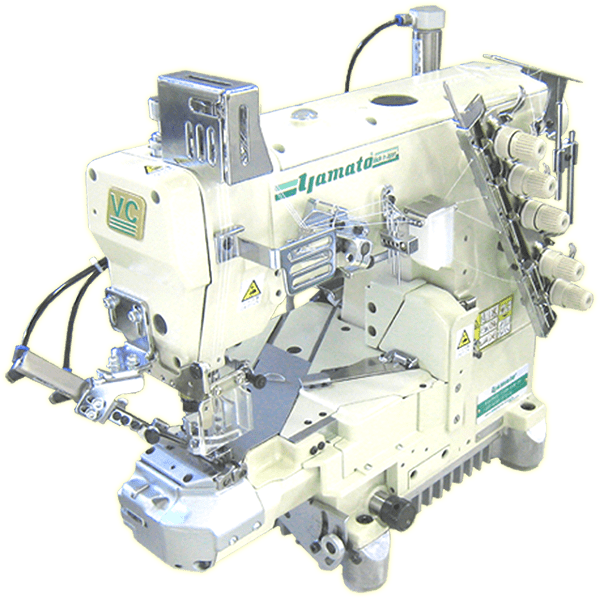

2,3 Needle Streamline Cylinder Bed Interlock Stitch MachineVC2790G-8F class

Streamline Cylinder Bed Makes Operator’s Handling Easier, for Improving Quality and Productivity.

- Streamline Cylinder Bed Makes Operator’s Handling Easier!

- Active Thread Control supports ideal seam over wide range from soft and elastic seams for microfibers to tight seams for outer wears.

- Yamato "Non-stain" Technology minimizes the risk of oil stain, the most frequent cause of defects.

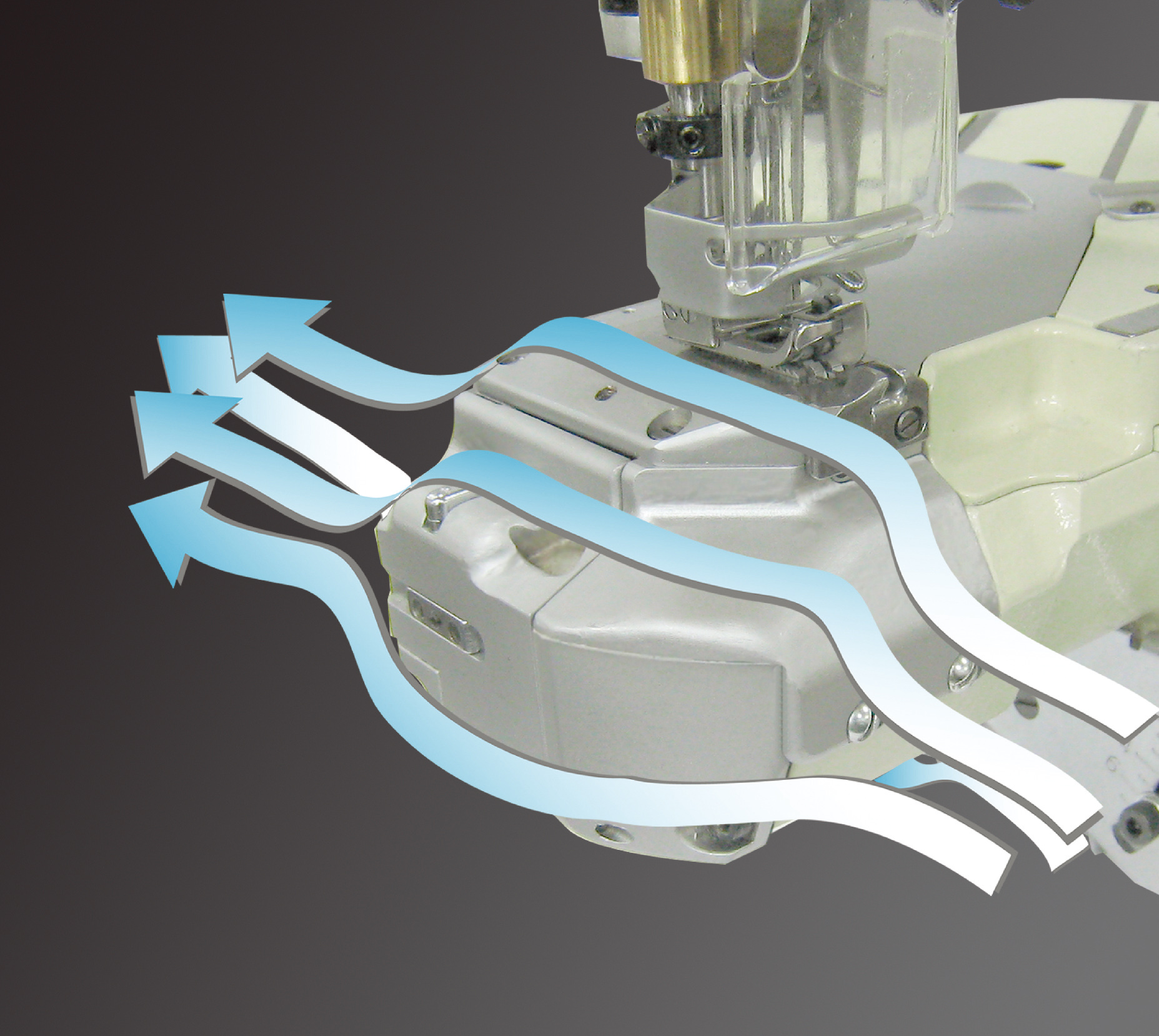

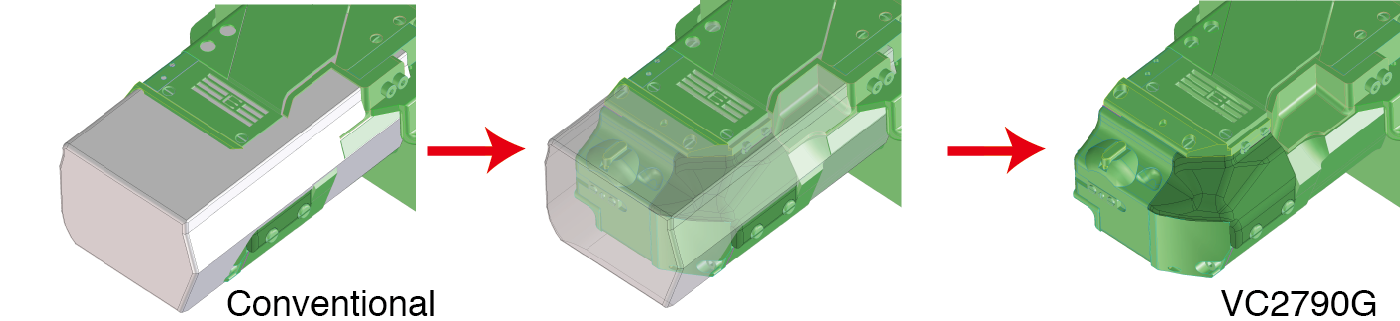

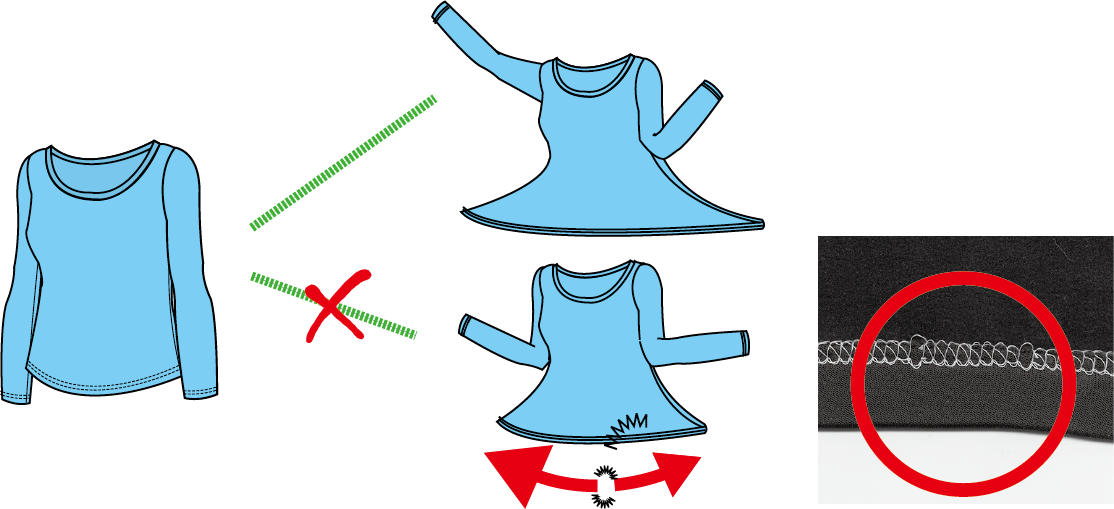

Streamline Cylinder Bed Makes Operator’s Handling Easier!

Streamline cylinder bed makes operator’s handling easier. Streamline may cylinder bed reduce setting, feeding and removing works when required with conventional cylinder bed interlock machines.

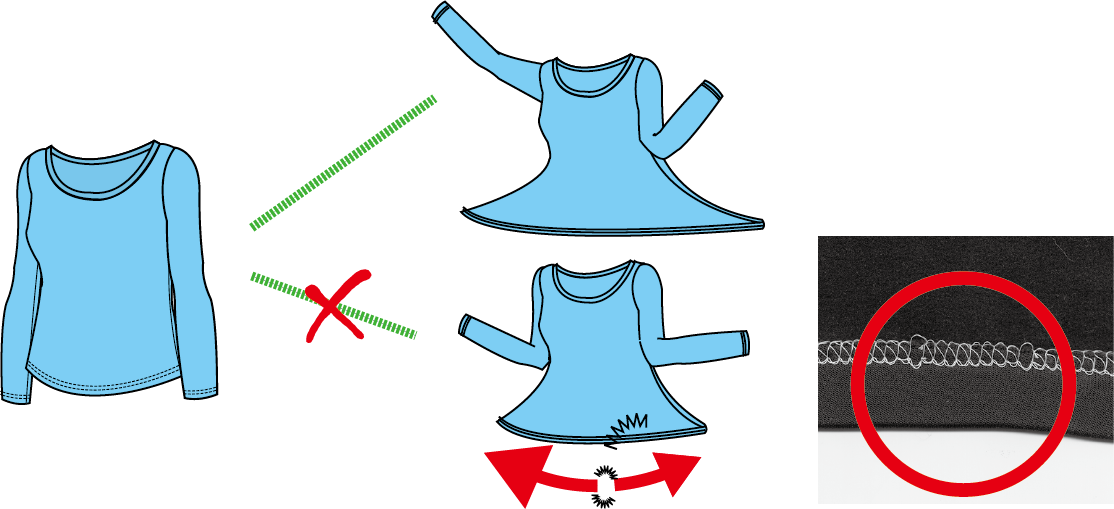

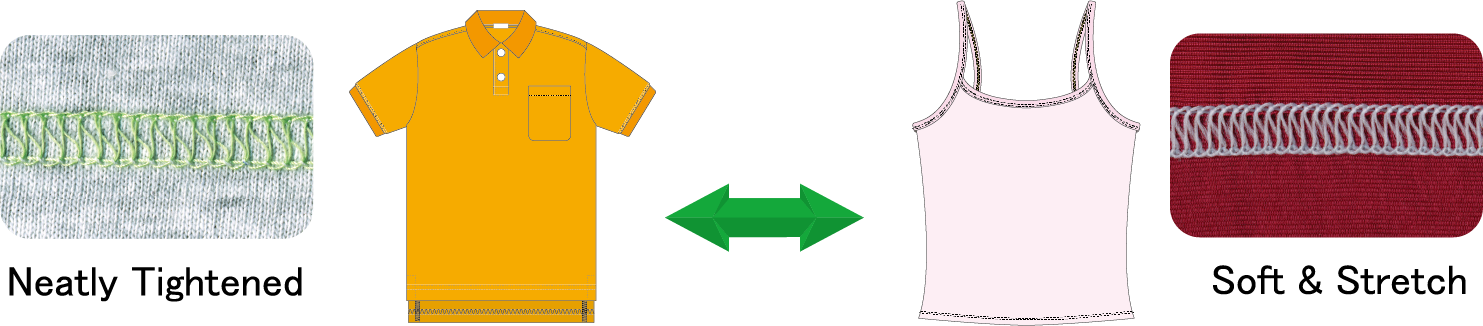

Yamato's signature Active Thread Control Technology

Active Thread Control supports ideal seam over wide range from soft and elastic seams for microfibers to tight seams for outer wears.

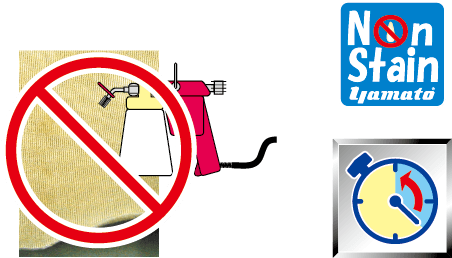

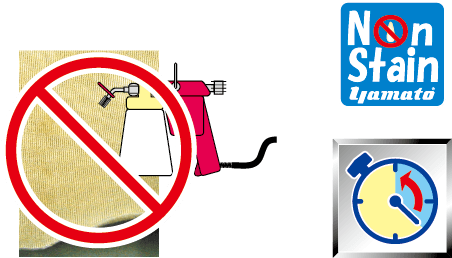

Yamato "Non-Stain" Technology

Yamato "Non-stain" Technology minimizes the risk of oil stain, the most frequent cause of defects.

Streamline Cylinder Bed Makes Operator’s Handling Easier!

Streamline cylinder bed makes operator’s handling easier. Streamline may cylinder bed reduce setting, feeding and removing works when required with conventional cylinder bed interlock machines. Averagely, efficiency of covering on T-Shirt was enhanced over 20% by using VC2790G!

Moreover, streamline cylinder bed helps you reducing defects and enhancing productivity by reducing operator’s tiredness.

Suitable for microfibers. Active Thread Control supports ideal seam over a wide range from soft and elastic seams for microfibers to tight seams for outer wears

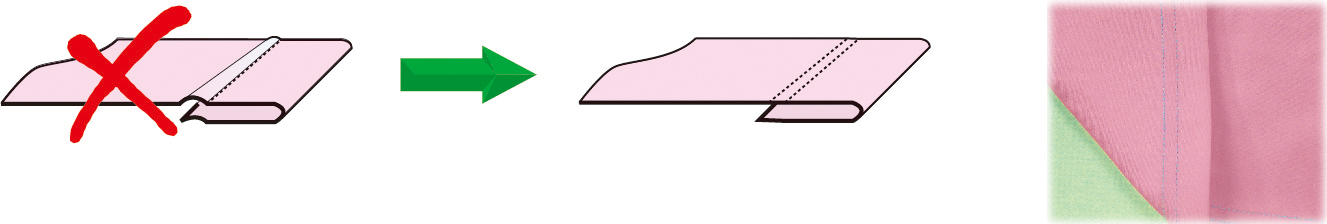

Epoch-making soft and elastic seams suitable for microfibers

If you are looking at further flexibility for the recent frequent and big change in sewing condition, Yamato's signature "Active Thread Control" is the right technology.

Active Thread Control performs epoch-making soft and elastic seams suitable for garments with lightweight, soft and stretchable microfibers, such as athletic wears or ladies' intimates.

Unlike the conventional way of thread control, which mainly use tension (resistance) on each thread, Yamato "Active Thread Control" takes in and draws back thread when it is required, and well-balanced seams with minimum necessary tension(resistance) for thread regulation.

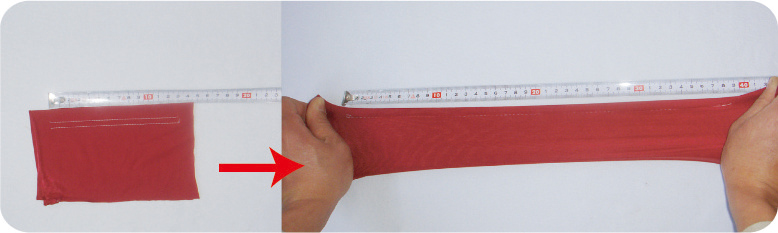

The soft and elastic seams made with Active Thread Control offer the tunnel free finish preventing seam breakage.

Tunnel Free Finish, Comfortable to Wear

200% plus stretch!

High streatch seaming prevents seam breakage.

Ideal seam over wide range from soft and elastic seams for microfibers to tight seams for outer wears

Making ideal seams over wide range, Active Thread Control supports wide variety seams from soft and elastic seams to tight seams. Yamato Active Thread Control makes ideal thread balance control to form any desiered seam, with less stress given to each thread.

Adjustment from soft to tight seam can be done simply and visibly, addressing frequent changes of sewing conditions.

Wide variety of seams can be performed with Active Thread Control, by the simple and "visible" adjustment, not by the "fuzzy" adjustment tension devices.

Adjustment from soft to tight seam can be done simply and visibly to minimize required skills and downtime spent for addressing frequent changes of sewing conditions.

Yamato "Non-Stain" Technology

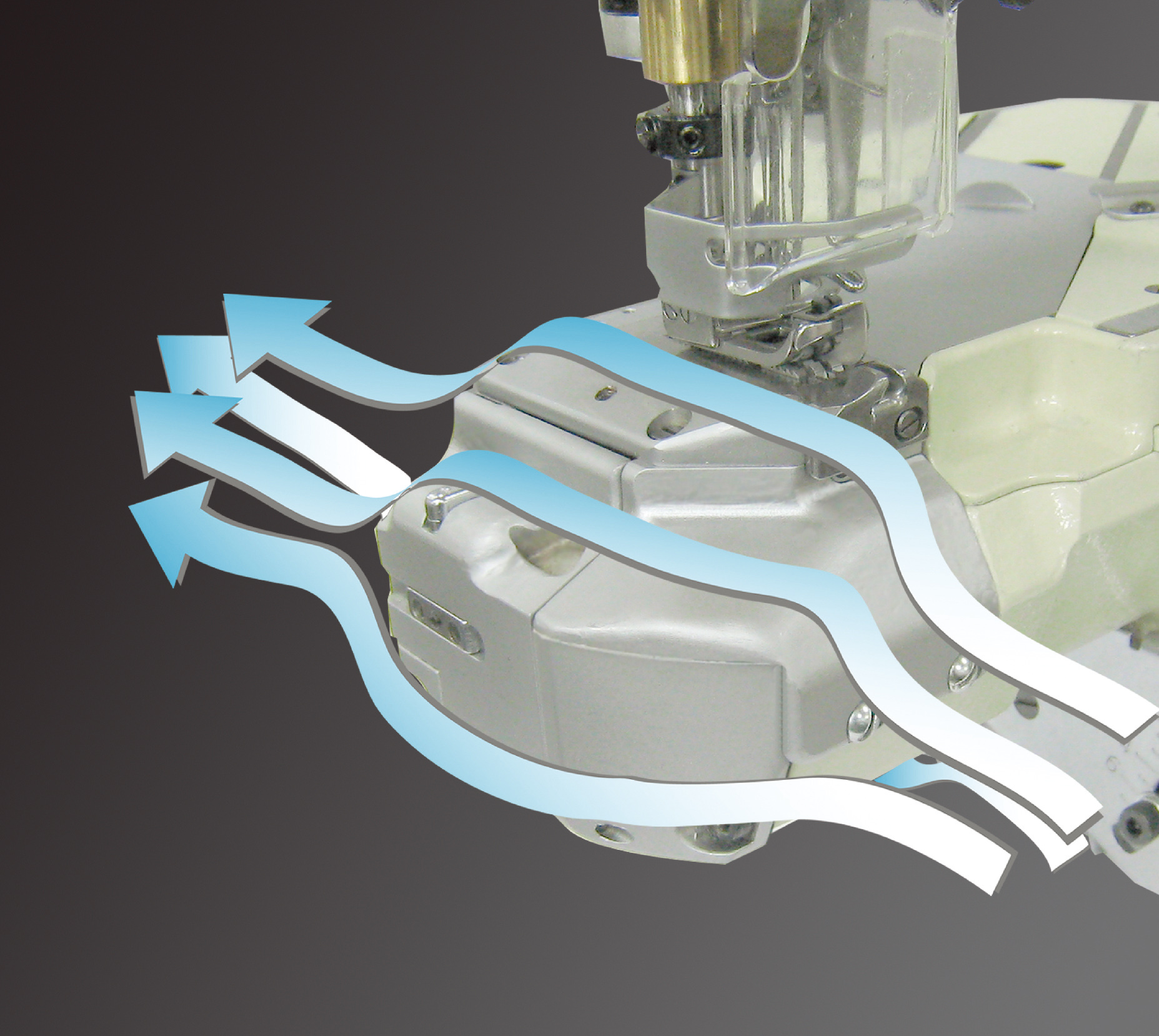

Yamato "Non-stain" Technology for minimizing the risk of oil stain, the most frequent cause of defects.

Yamato's "Non-stain" technology will not sacrifice the performance and the durability of machines, but keep the machine running smoothly at high speed for long life.

While giving enough lubrication for the internal driving mechanism, Yamato exclusive sealing sytem prevents the oil from coming to the sewing area through moving parts. This feature minimizes the risk of oil stain, one of the most frequent cause of defects.

Non-stain finish minimizes your loss, such as downtime and extra cost caused by spot removing operations

Less friction, Less Lubrication

Much less lubrication than conventional machines are required thanks to high-tech mechanical parts dramatically reducing frictions.

The oil is pumped to needle bar crank area, all way through upper shaft. Thanks to "forced lubrication", very small, but stable amount of oil is always given to exactly where it is necessary, and ensures less risk for leakage while maintaining machine performance.

Special Seals Prevent Oil Leakage

Special sealing mechanism is installed on each bushing above fabric and sewing cylinder area.

These seals are designed to prevent oil excess from dripping on fabric, by wiping oil film away from surface of moving parts.

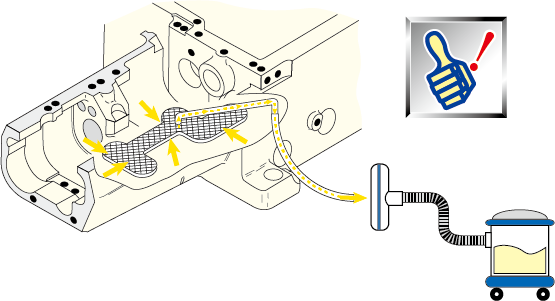

Excess Oil is Collected and Circulated

Wiped oil excess is collected by pump force to be cooled down and filtered for next cycle of lubrication.

Versatility

Can be applicable for Covering, Hemming and Binding operations.

Easy Maintenance

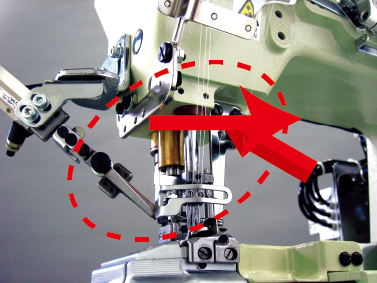

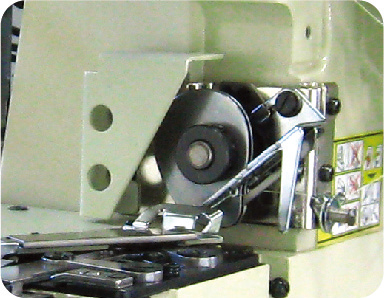

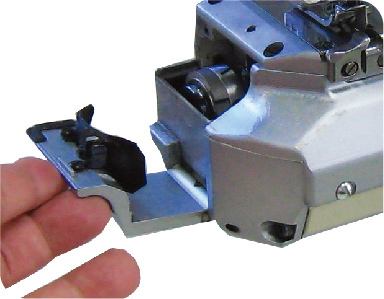

Looper Thread Take-up Cam System

The cam is located outside of the machine frame for easy adjustment and removal.

Downtime to unwind looper thread in case of it winds itself around the cam is dramatically shortened. Also, the cam can be exchanged easily according to different sewing conditions.

Openable Side Cover

Side cover is openable for easy feed dog height adjustment and cleaning.

日本語

日本語  中文

中文