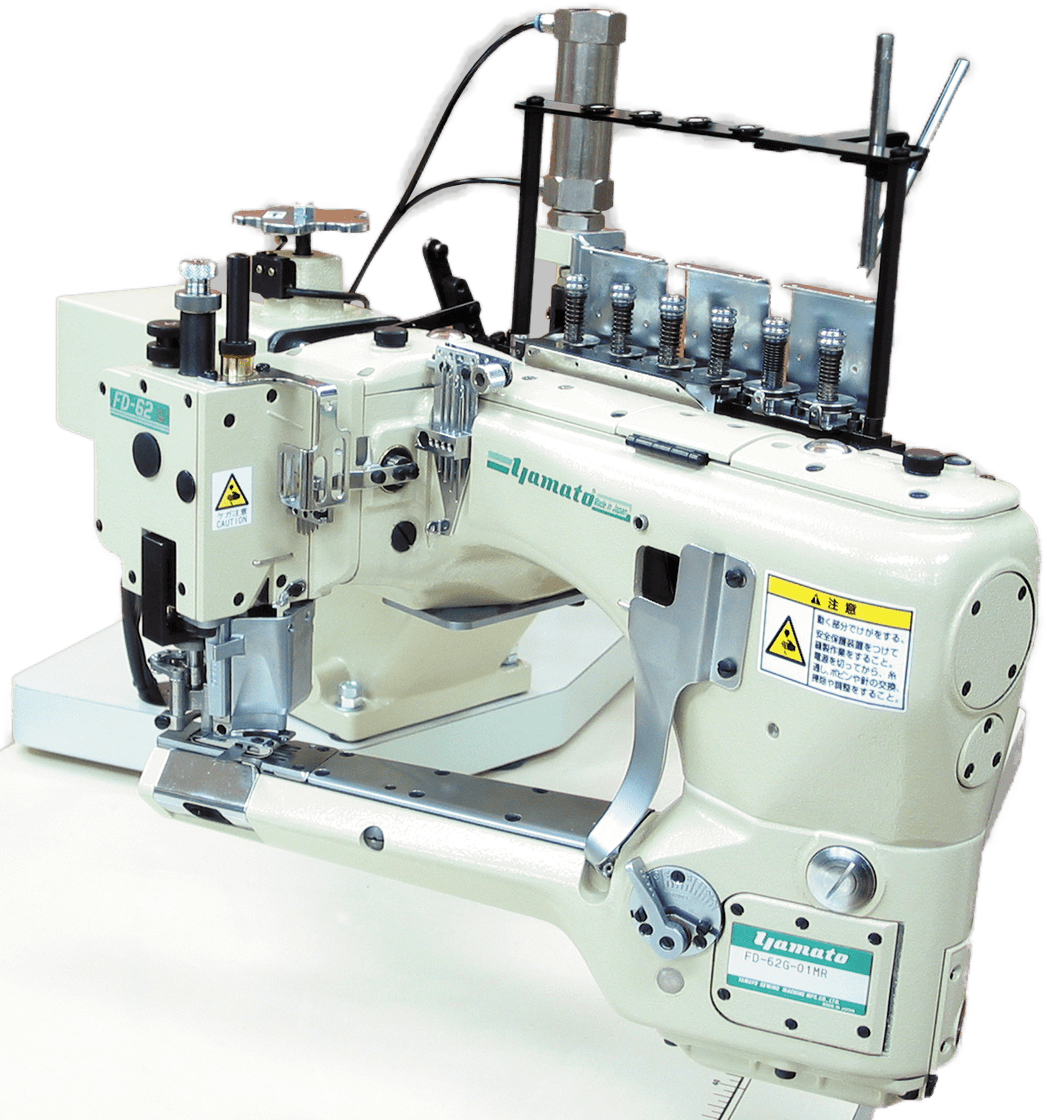

4 Needle 6 Thread Flat-seamer, Feed-off-the-ArmFD-62G series

With its high performance and wide choice of submodels for various sewing conditions, which keep satisfying leading garment manufacturers worldwide, you can obtain further enhanced quality of your products while minimizing production downtime.

- Ensures smooth feeding of various fabric; from single jersey to fleece, stretchable and uneven thickness portion. Besides, overlapping amount of upper / lower fabric is easily adjustable.

- Yamato "Non-stain" Technology minimizes the risk of oil stain, one of the most frequent cause of defects.

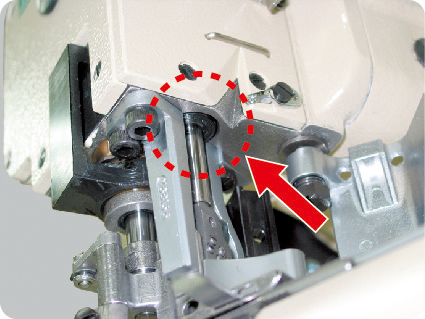

Yamato "Non-stain" Technology for minimizing the risk of oil stain, the most frequent cause of defects.

Yamato "Non-stain" Technology

While giving enough lubrication for the internal driving mechanism, Yamato's exclusive sealing system prevents the oil from coming to the sewing area through moving parts. This feature minimizes the risk of oil stain, one of the most frequent cause of defects.

Saving - "Non-stain" increases productivity.

Non-stain finish minimizes your loss, such as downtime and extra cost caused by spot removing operations.

Good performance and long life - durable machines

Yamato's "Non-stain" technology will not sacrifice the performance and the durability of machines, but keep the machine running smoothly at high speed for long life.

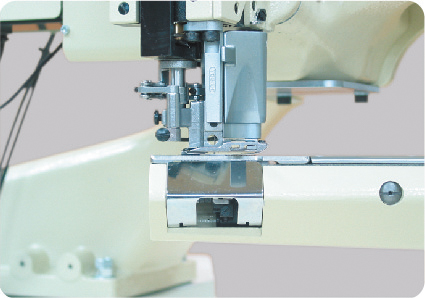

Pressor Foot Floating System

The system ensures smooth feeding of various fabric; from single jersey to fleece, stretchable and uneven thickness portion. Besides, overlapping amount of upper / lower fabric is easily adjustable.

Small Cylinder for Easy Small Tubular Operations

Cylinder circumference at the needle dropping point is 148 mm. This small cylinder enables small tubular operations. Also, long cylinder of 200 mm before needle dropping point provides a wide operation space.

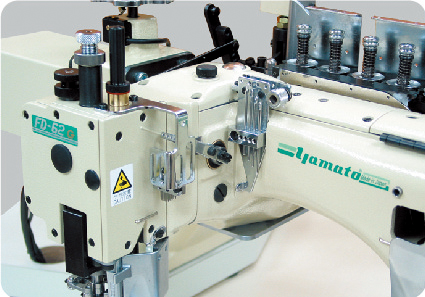

Differential Feed Amount

Easily adjustable by outer lever.

Needle Thread Tension Adjustment

Tension can be adjusted individually for neat stitch formation.

日本語

日本語  中文

中文