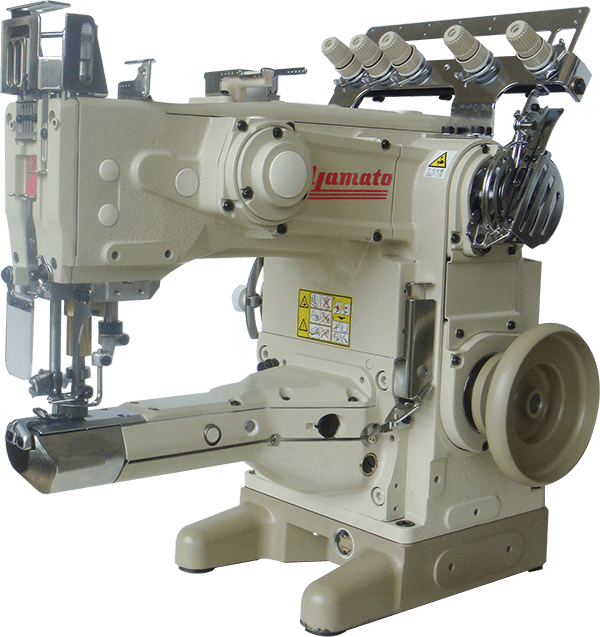

Economy type Feed-up-the-Arm Interlock Stitch MachineVT1500 series

Yamato's VT Series is dedicated to ideal sewing experience, you never had before! The machine can perform neat and uniform finish on both lightweight and heavy weight fabric with little adjustment. Furthermore, various fabric guides enable sewing covering, hemming, binding freely.

- High-lift needle bar mechanism and ideal stitch formation enable smooth feeding for wide range of materials, without having stuck by cross seam with fleece or tunnel seam with single jersey.

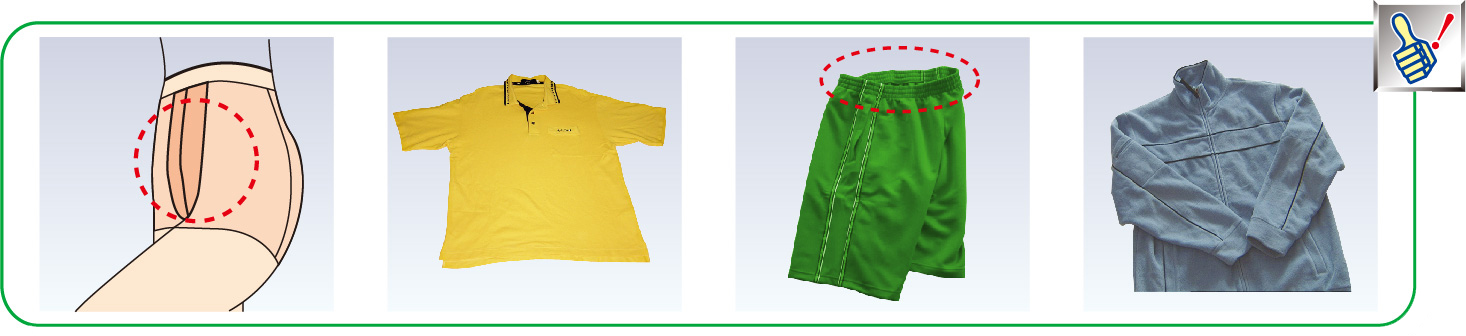

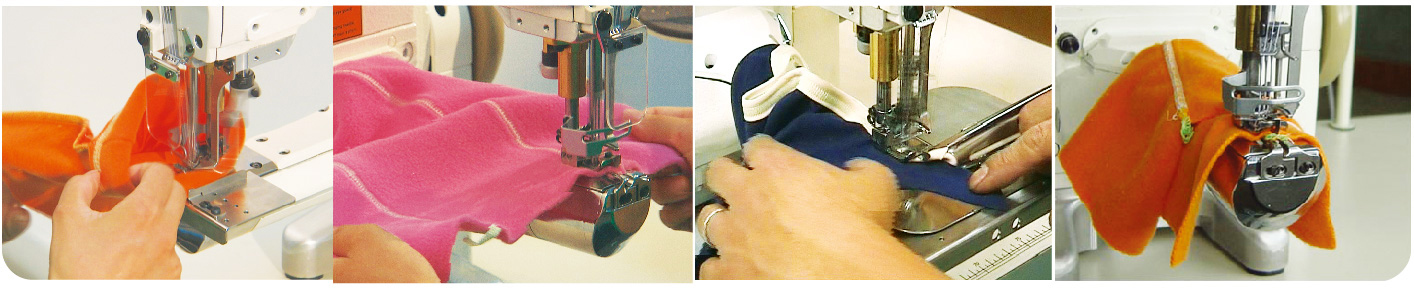

- With free handling space around the needle drop area, you can easily handle small circulars like cuff, ankle, neckline, and sharp curbs for jointing shoulder with neck.

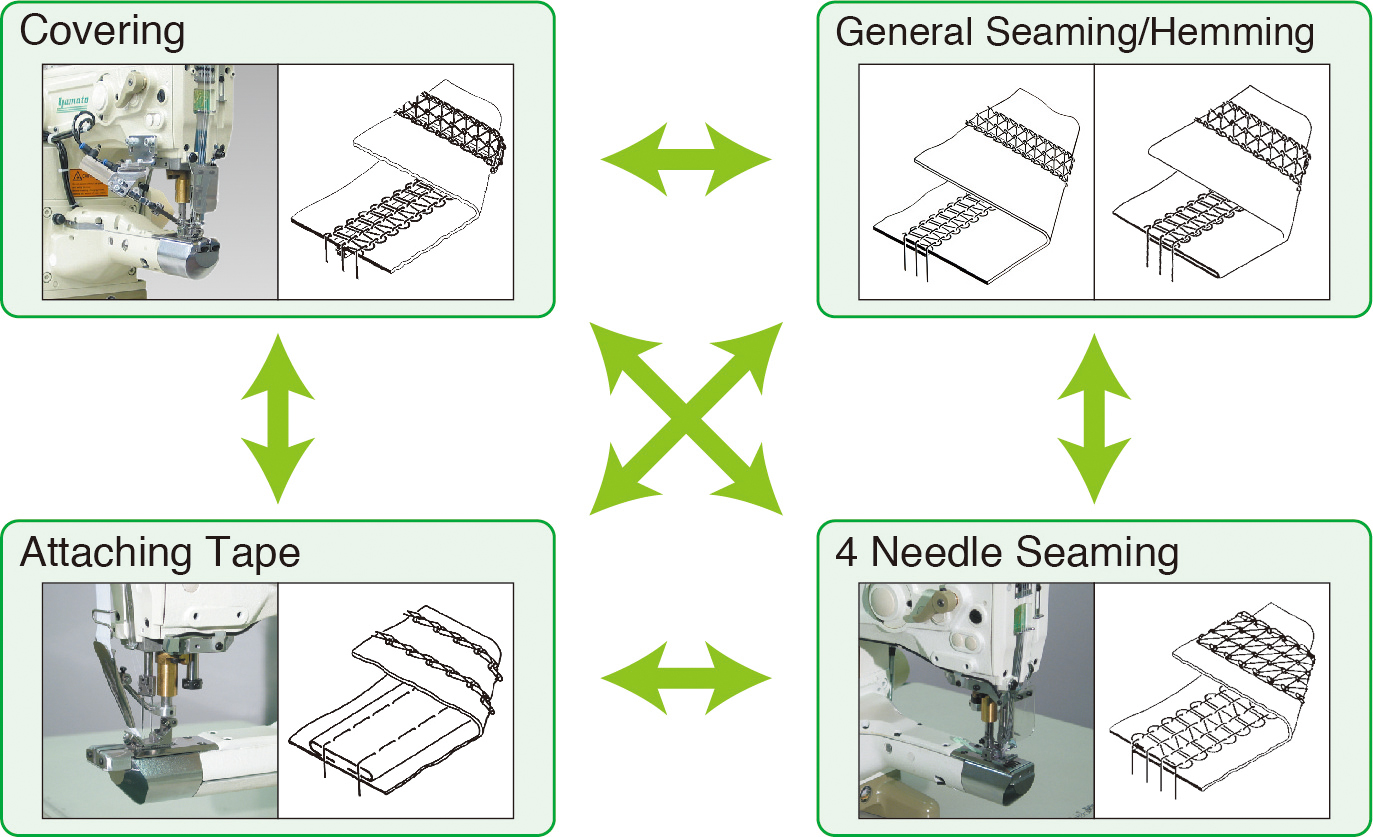

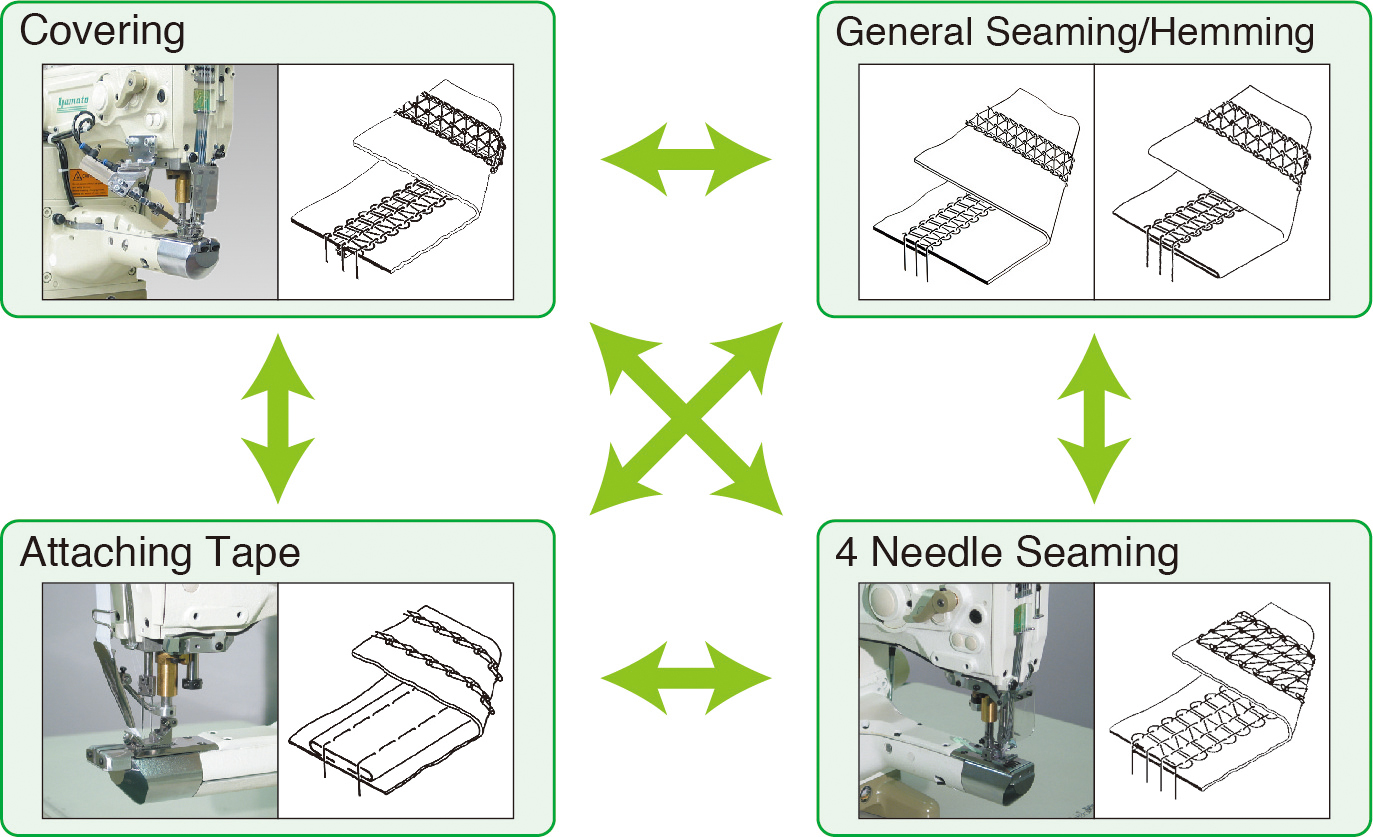

- By simply exchanging thread eyelets and sewing parts, the versatile machine can be converted into any types of available Submodels for covering, attaching tapes and 4 needle seaming.

- Yamato Non-Stain technology will minimize the risk for oil stain without sacrificing the performance and durability of machines. Further enhanced quality and minimized production downtime is expected.

Valuable choice for heavy-weight materials

High-lift needle bar mechanism and ideal stitch formation enable smooth feeding for wide range of materials, without having stuck by cross seam with fleece or tunnel seam with single jersey.

Easy Handling

With free handling space around the needle drop area, you can easily handle small circulars like cuff, ankle, neckline, and sharp curbs for jointing shoulder with neck.

Easy Conversion into Submodels

By simply exchanging thread eyelets and sewing parts, the versatile machine can be converted into any types of available Submodels for covering, attaching tapes and 4 needle seaming.

Valuable choice for heavy-weight materials

High-lift needle bar mechanism and ideal stitch formation enable smooth feeding for wide range of materials, without having stuck by cross seam with fleece or tunnel seam with single jersey.

Differential feed mechanism is included as a standard equipment, for perfect stitching & seaming

Differential feed as a standard equipment for "no wave" finish

Rear Needle Guard is driven independently to prevent broken needles and skipping stitch

Push Button for adjusting Stitch Length for wide variety of applications

Easy Handling

With free handling space around the needle drop area, you can easily handle small circulars like cuff, ankle, neckline, and sharp curbs for jointing shoulder with neck.

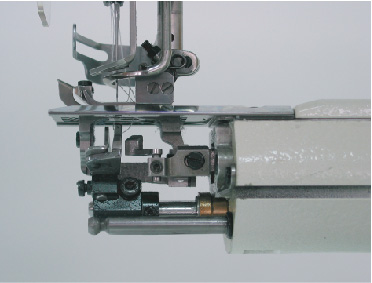

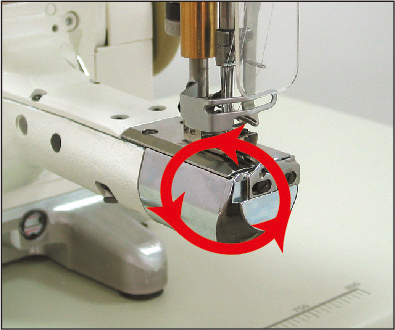

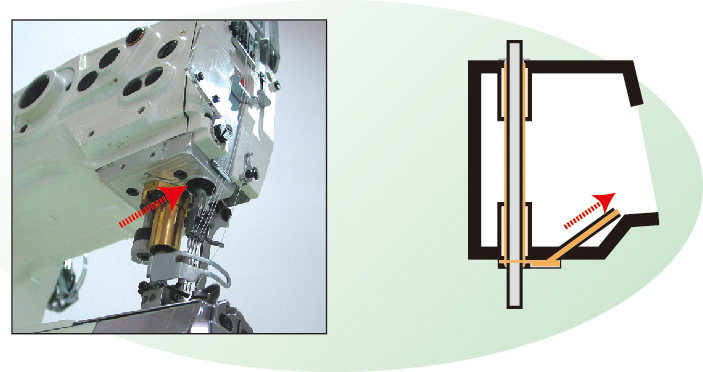

For a machine with UT device, the trimming mechanism is installed inside the cylinder bed to secure the space around the needle drop area.

UT device, the trimming mechanism is installed inside the cylinder bed

Various features for easy handling

External Thread Take-up for smooth supply of threads

Spreader locates on right side for easier and safer handling

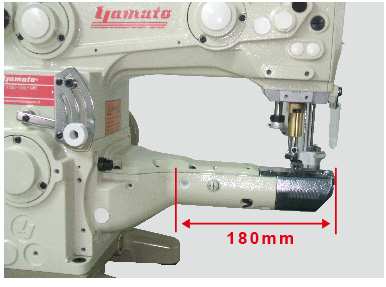

Cylinder length is wide enough as 180mm

Easy Conversion into Submodels

By simply exchanging thread eyelets and sewing parts, the versatile machine can be converted into any types of available Submodels for covering, attaching tapes and 4 needle seaming.

Non-Stain

Yamato Non-Stain technology will minimize the risk for oil stain without sacrificing the performance and durability of machines. Further enhanced quality and minimized production downtime is expected.

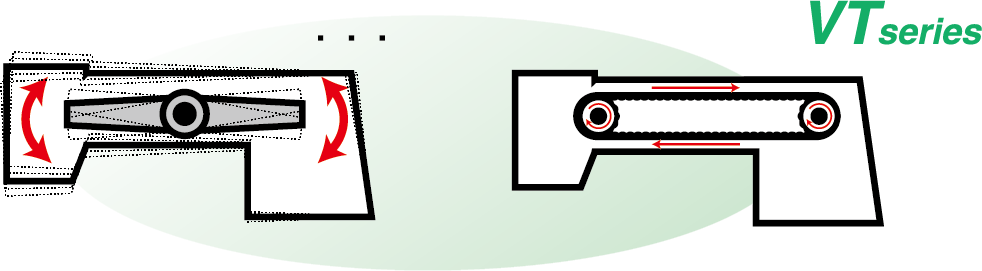

Vibration-Free Driving Mechanism Eliminates Operators' Fatigue

Epoch-making "vibration free" mechanism minimizes the noise and vibration, which minimizes the fatigue of operators, and consumedly decreases the unstable operation and injuries, enhances the productivity, ensures uniform finish! Moreover, low noise/little vibration proves less abrasion of the machine, which guarantees its longer running life.

日本語

日本語  中文

中文