Lockwelt Series Advanced Pocketwelting MachineAMF Reece Series 39

Advanced Pocketwelting Machine for All Types of Welted Pockets

- AMF Reece Series 39 can be used for all types of welted pockets and is ideal for all seg- ments of the apparel industry.

- Available models and a range of optional accessories make the machine capable for use on a wide variety of applications. Series 39 is capable of sewing at high speeds of up to 3,000 spm.

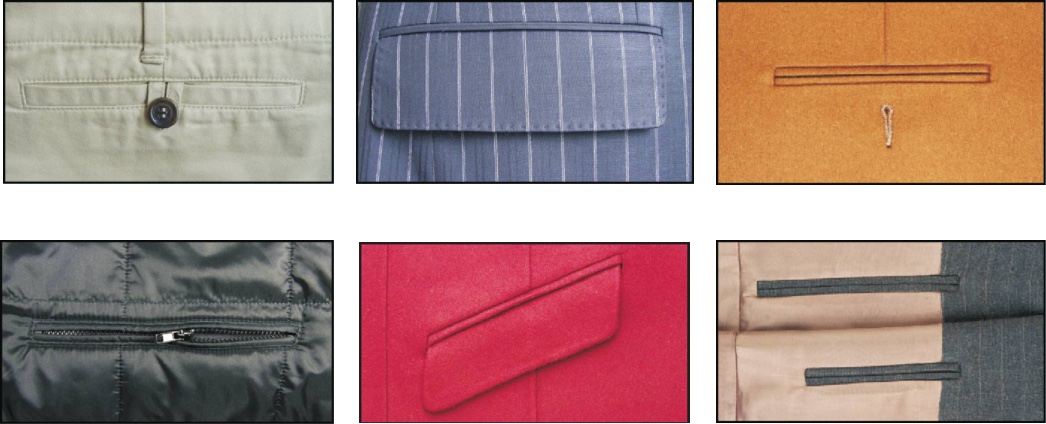

Wide Variety of Application

Available models and a range of optional accessories make the machine capable for use on a wide variety of applications.

High Quality & Productivity

Capable of high quality sewing at high speeds of up to 3,000 spm.

Automation

All models equips with intuitive touch screen display. It is possible to program 10 different pocket styles with individual sewing functions and parameters assigned.

Wide Range of Application

Easy Adjustment and Maintenance

Wide Range of Application

Wide Range of Application

AMF Reece Series 39 can make for all types of welted pockets such as Single, Double, Offset with or without flap.

Series 39 can be used for formal, informal men's/ladies'/kid's wear (suits, trousers, jackets, coats, skirts, vests), leather jackets, sportswear, workwear, ladies‘ handbags‘ zipped pockets.

Single and Double Welt Folders are supplied as standard with the machine.

Eight bite sizes are available as options from 8-24 mm in 2 mm increments (the bite size must be specified at time of order).

AP Models

Capability of making true slanted welts

The AP versions include all of the features of the standard machine plus the added capability of making true slanted welts. The two independently driven needle bars can start and finish sewing offset by up to 5 mm (see below the diagram) thanks to use of a split needle sewing head. This allows the machine to sew either straight or angle welts with and without pocket flap insertion.

The AP model uses 3 sets of tab knives providing accurate corner cutting in all applications. The machine can automatically alternate between left and right side pockets or sew all the welts both inside and outside of a garment in sequence.

High Quality Finish

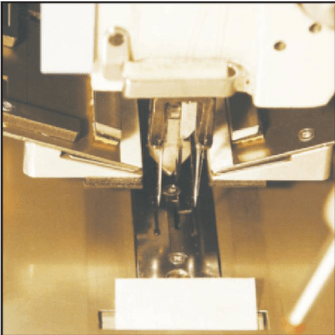

Stationary Tab Knives

Stationary Tab Knives combined with the AC Servo motor controlled carriage movement ensures high quality corner cutting on all kinds of fabric.

The Series 39 machine can be equipped with step motor controlled tab knife system in combination with a step motor fabric feed as opposed to stationary tab knives and servo motor feed which is the standard version. The step motor control system is optional and needs to be specified when ordering the machine.

Automatic Flap Sewing

Automatic Flap Sewing, on left or right welts, is possible with the help of a photocell system fitted as standard on the machine. Independent clamping can be activated if the operator prefers to spread the fabric before sewing operation.

Pocket Bag Clamp

Pocket Bag Clamp is used for securing the pocket bag material while the operator loads the panel.

Centre Knife

Centre Knife is controlled by an independent DC motor that is fixed on the machine sewing head.

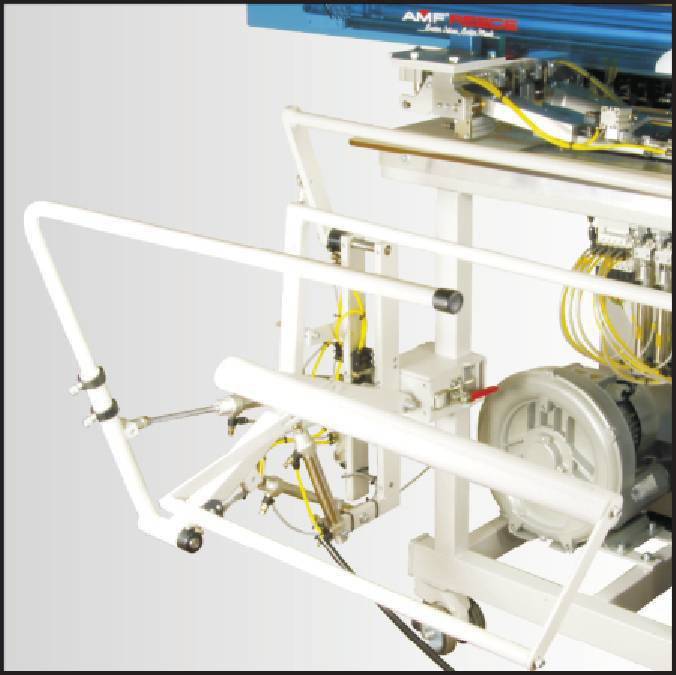

Vacuum System (Optional)

The Vacuum System is recommended to be used for sewing welts into the back panels of trousers which have a dart seam. The system can be used with its own independent vacuum motor or hooked up to the existing plant vacuum system.

Dart Stretcher (Optional)

Dart Stretcher is used for eliminating fabric fullness before clamping and sewing.

Sandwich Clamp Kit for preventing puckering (Optional)

Sandwich Clamp Kit is recommended for lightweight fabrics not to slip during sewing cycle. This device uses clamp arms lower support plate that is attached to the carriage. The support plate travels back and forth with the carriage, aiding in the transport of material and preventing puckering during the sew cycle.

Needle-Feed Mechanism for elastic difficult materials (Optional)

Needle-Feed Mechanism ensures that the material moves while the needle is in the material. This is especially advantageous when sewing on difficult materials such as slippery, thin, elastic fabrics etc.

Automation

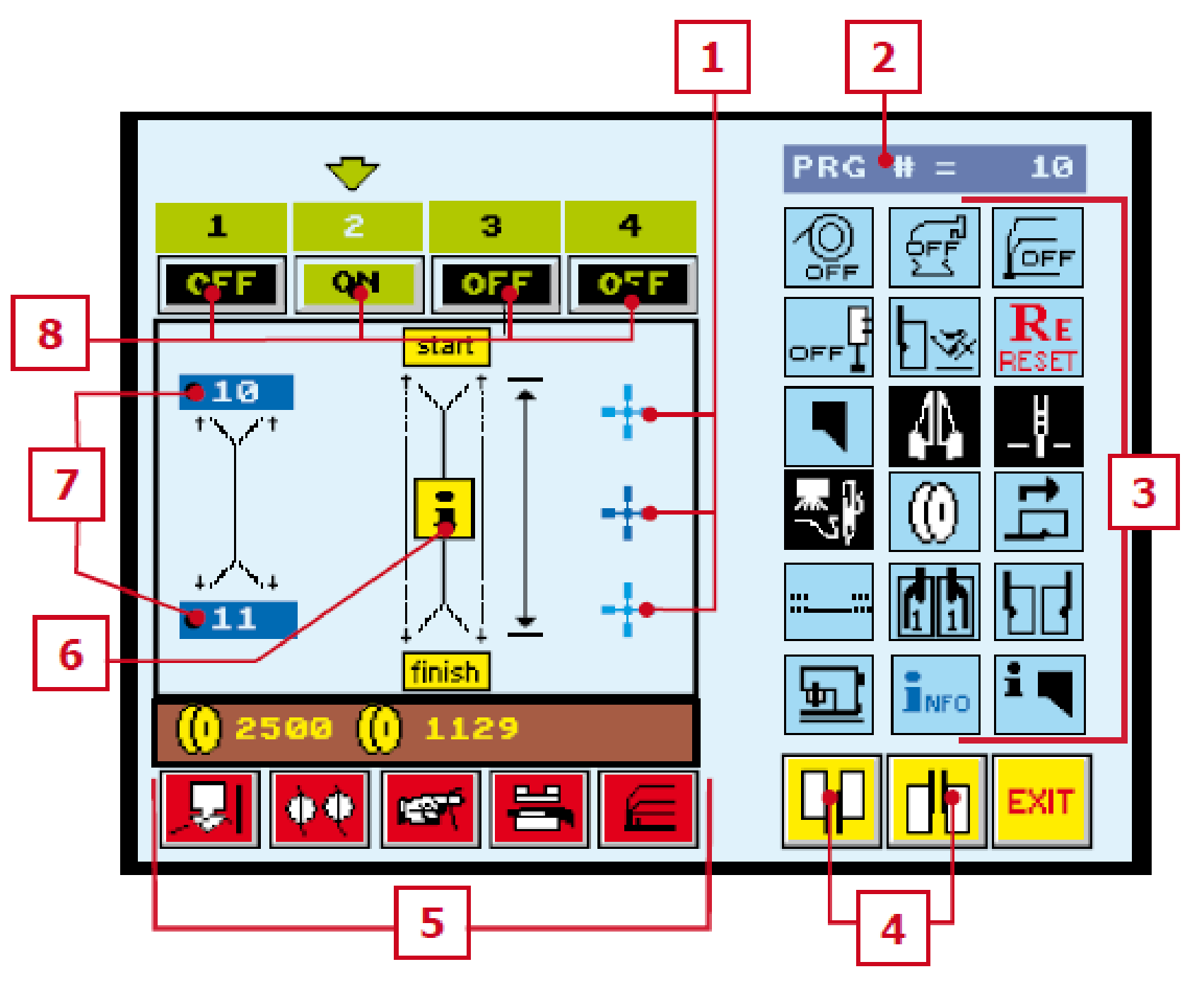

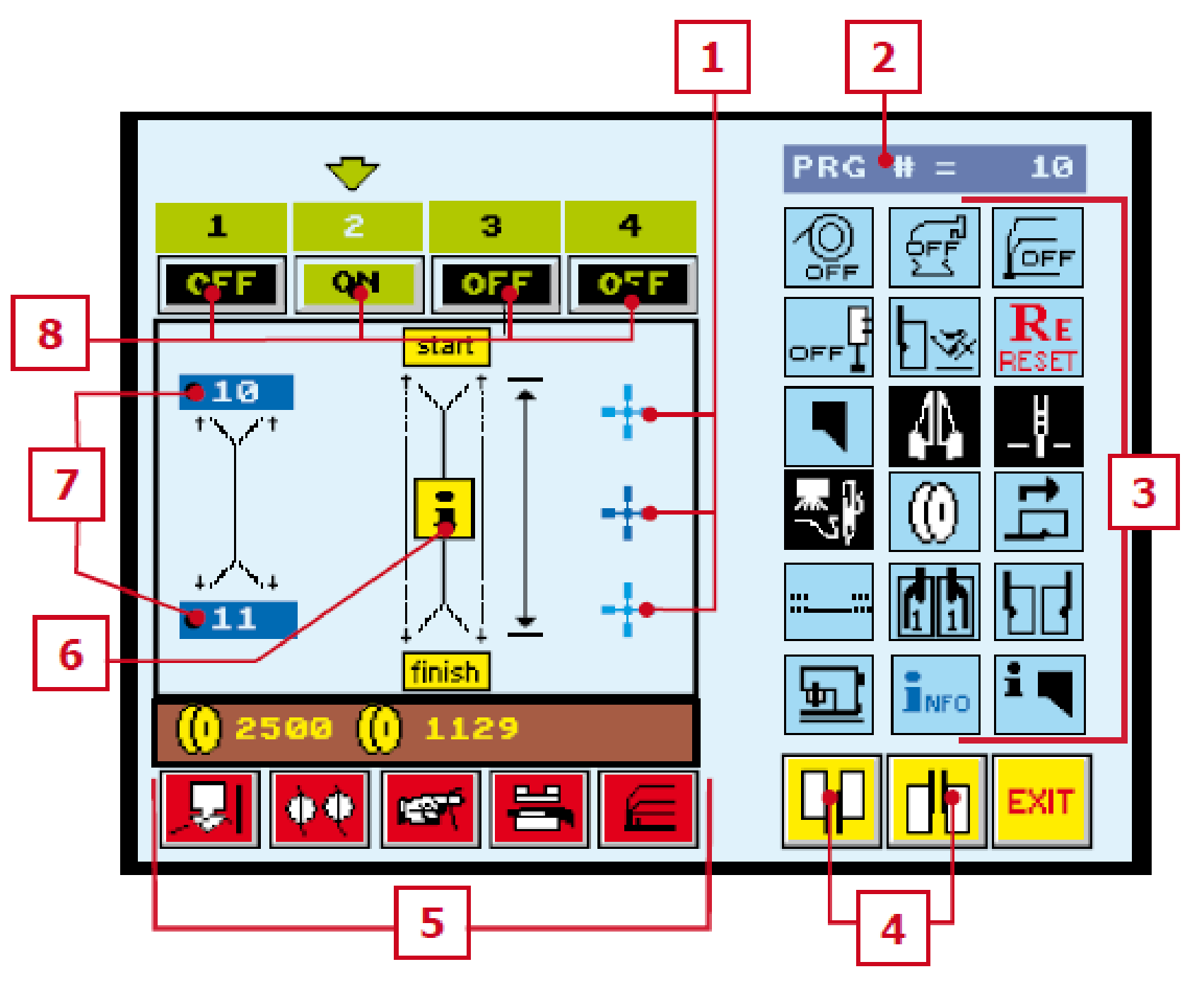

Ease of Use with the Touch Screen Display

All pocketwelting machines are equipped with 5,7” graphic touch screen display that provides the operator with a user friendly working environment and with icons for every operation required to sew the perfect pocketwelt.

It is possible to program 10 different pocket styles with individual sewing functions and parameters assigned.

Optionally, the Series 39 machine can be equipped with a full-color touch screen display using the same icons.

Functions of the touch screen

- Sewing Position Selection

- Pocketwelt Program Selection

- Optional Adjustments and Functions

- Carriage Position Selection

- Function Buttons for Thread Tension; Stacker, Auto Tape, Thread Trimmer

- Pocketwelt Adjustments

- Tab Knife Adjustments

- Cycle Mode (Pocketwelt ON/OFF)

Cycle Sewing

Allows the sewing of different types of welts in alternating combinations

Cycle Sewing allows the sewing of different types of welts in alternating combinations. Up to 5 pocket styles can be selected from the control panel for cycle sewing.

Top Thread Monitor

Top Thread Monitor is fitted as standard and stops the machine when a thread break occurs.

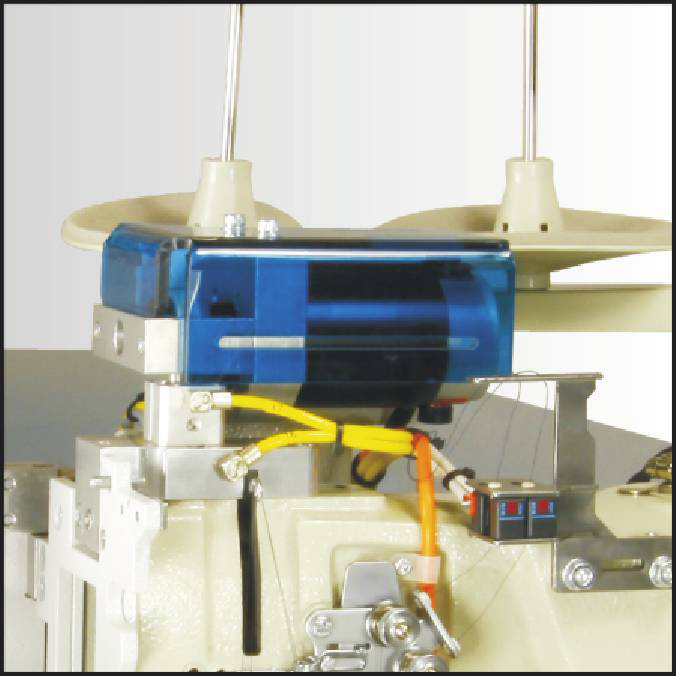

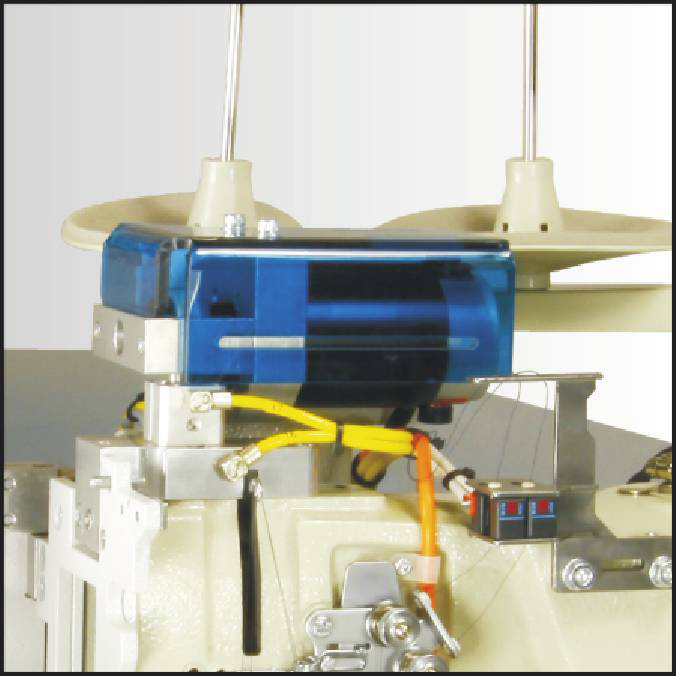

Bobbin Winder

Bobbin Winder is located on the sewing head minimizing down time when changing bobbins.

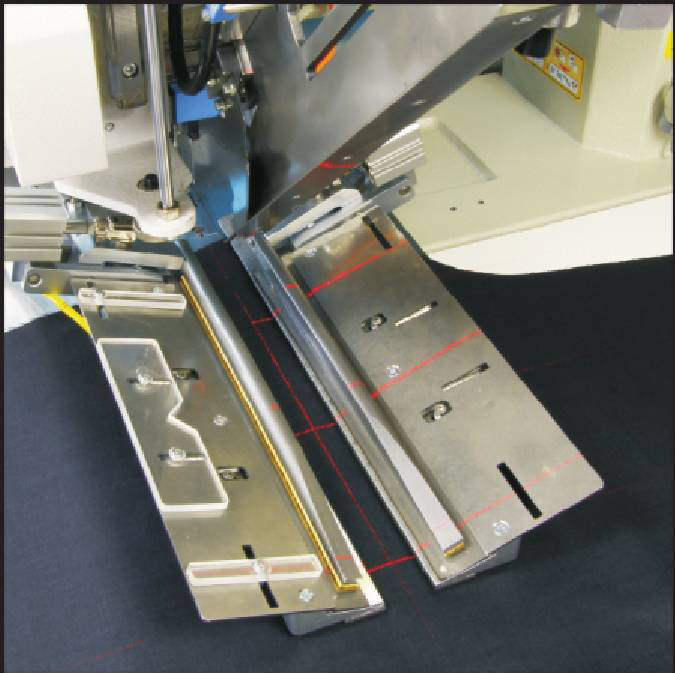

Laser Lights

Laser Lights are supplied as standard (3 sets) for easy placement of the fabric panel.

These eliminate the need for manual marking on both trouser and jacket welting operations.

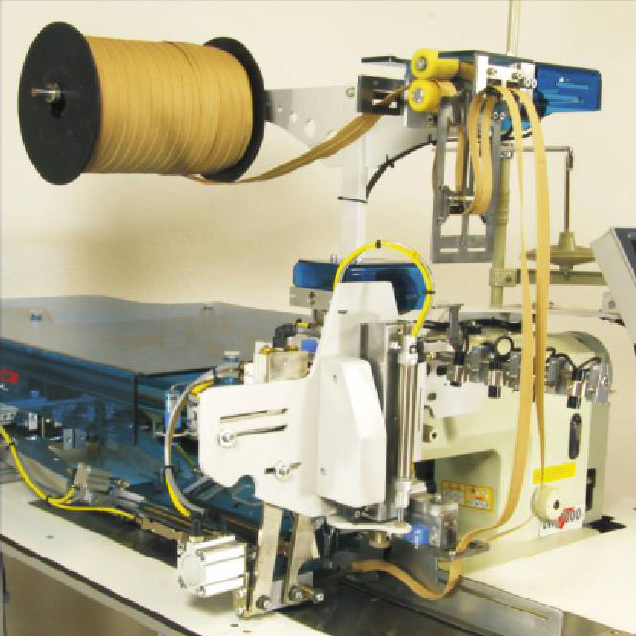

Auto Tape Feeder (Optional)

Auto Tape Feeder is available for automatic loading and cutting of interfacing.

Universal, Trouser Stackers & Work Remover (Optional)

Universal and Trouser Stackers are available to remove the panels from the machine to increase productivity.

An optional Work Remover should be used for shorter panels.

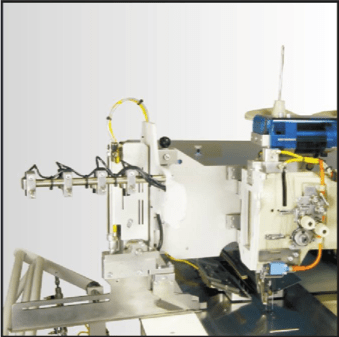

Automatic Patch and Flap Loader (Optional)

The Automatic Patch and Flap Loader allows the operator to utilize the sewing time by pre- loading the patch and flap ready for the next cycle.

Zipper Attachment (Optional)

Zipper Attachment allows two sides of the endless plastic zipper to be inserted automatically from a roll above the machine into the welt during the sewing cycle.

At the end of the sewing cycle, the zipper is cut to the exact length.

Only plastic zippers can be used (Needle distance: 12 - 18 mm) .

At the end of the sewing cycle, the zipper is cut to the exact length.

Easy Adjustment and Maintenance

Easily Adjustable Clamp Feet

Clamp Feet position (lateral distance, in or out) and clamp feet pressure can be simply adjusted especially when sewing on difficult materials.

Quick Change Kit

Quick Change Kit as a standard accessory allows the operator to sew either single or double welts by a simple change of the patch guide.

Swing out Folding Station

Swing out Folding Station can be opened for easy access in case of re-threading and bobbin changes.

Tilt Back Sewing Head

Tilt Back Sewing Head allows easy maintenance.

日本語

日本語  中文

中文