Electronic Eyelet Buttonhole MachineAMF Reece ES-505

Ultraflex

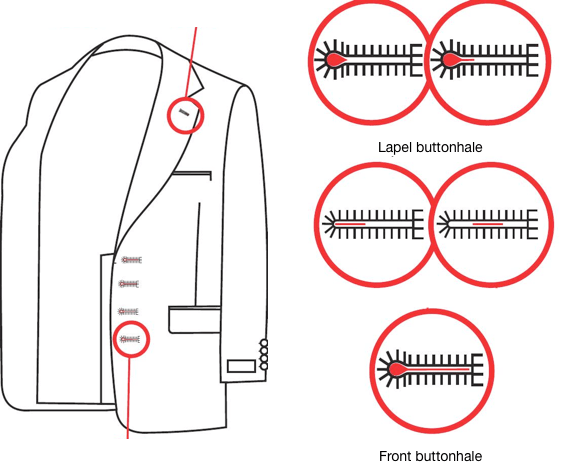

Ultra Flexibility on Men's Suit Applications

The Ultraflex is a specially designed model for button- hole applications on men’s suit which increases the operator’s productivity since both lapel and jacket front buttonholes are sewn and cut in one sewing sequence without changing any knives and cutting blocks. The lapel buttonholes are cut fully or partially.

All buttonhole parameters including the required cut- ting position and cutting length of the lapel buttonho- le is easily saved in the memory. The machine can be optionally equipped with an optical sensor system to automatically alternate between lapel and front but- tonholes.

The Ultraflex is supplied with LTT-long tail thread trimming mechanism. The machine is equipped with the thread nipper to ensure that the first buttonhole stitch is formed properly.

| Cutting Length (Eye Buttonhole) | 5~30 mm |

|---|---|

| Cutting Length (Straight Buttonhole) | 8~25 mm |

| Sewing Length | 13~30 mm |

AFS Model: For jacket sleeves

AFS model is recommended for sewing of regular eyelet buttonholes with single thread, ranging from 10 to 50 mm in length on jacket sleeves.

Model is supplied with thread nipper that holds the top thread at the start of sewing, to ensure that the first stitch is formed properly especially on difficult fabrics.

CTS Model: For jacket sleeves

CTJ Model: For jeans fly fronts

Both models are used for applications with double thread, with or without gimp where all threads are trimmed from the very end of the buttonhole. A buttonhole length of 13 to 35 mm can be sewn with use of different clamp sets.

The CT model for jacket sleeves application is also equipped with the top thread nipper, which especially helps on crossbar buttonhole applications.

日本語

日本語  中文

中文