Electronic Eyelet Buttonhole MachineAMF Reece ES-505

New revolutionary design, four patented mechanisms, currently the highest sewing speed in the market, excellent traditional buttonhole quality, large full color touch screen display – all presented in the new AMF Reece electronic eyelet buttonhole machine ES-505.

- The ES-505 machine can be used for a wide range of applications which are suited to all needs of the clothing manufacturer, both large and small. This machine can handle all types of garments ranging from light to heavy weight materials including denim and leather. The applications of the machine can be found on formal menswear, ladies‘ wear, jeans, casual trousers and other outwear.

- Currently the fastest machine available, running at 2,700 spm. New vertical cutting system enables clean ad realiable buttonhole cutting.

- Stitch type, length, cycle sewing and patterns can be set on ES-505's intuitive touch panel display

Wide Range of Application

The ES-505 can handle all types of garments ranging from light to heavy weight materials including denim and leather. The applications of the machine can be found on formal menswear, ladies‘ wear, jeans, casual trousers and other outwear.

High Quality & High Productivity

Currently the fastest machine available, running at 2,700 spm. New vertical cutting system enables clean ad realiable buttonhole cutting.

Features for Automation

Stitch type, length, cycle sewing and patterns can be set on ES-505's intuitive touch panel display

Wide Range of Application

Features for Automation

Wide Range of Application

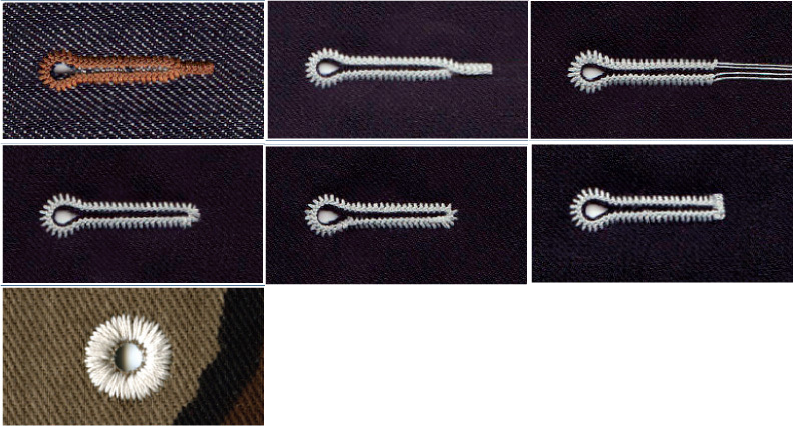

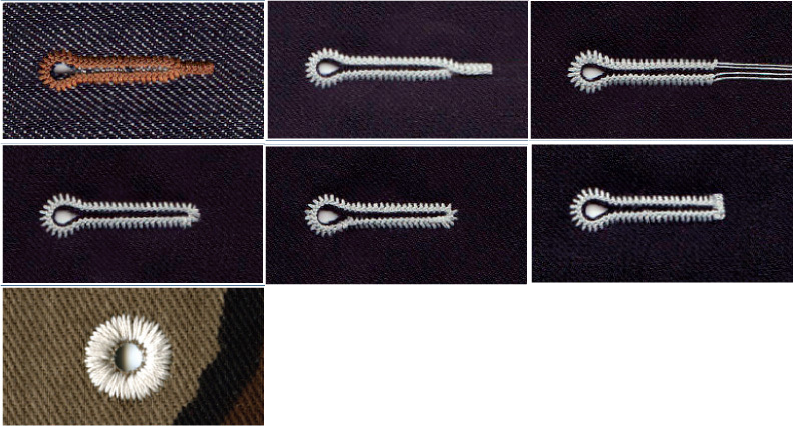

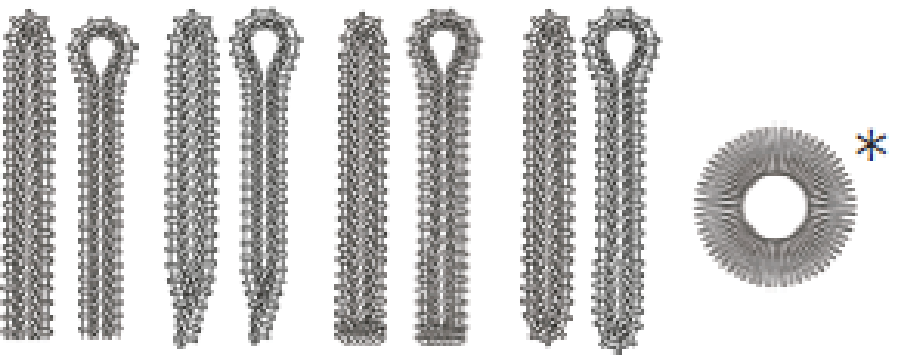

Applications and Sewing Patterns

The ES-505 machine can be used for a wide range of applications which are suited to all needs of the clothing manufacturer, both large and small. This machine can handle all types of garments ranging from light to heavy weight materials including denim and leather. The applications of the machine can be found on formal menswear, ladies‘ wear, jeans, casual trousers and other outwear.

The ES505 machine can sew a variety of buttonhole shapes with or without gimp including the round eyelet. Depending on the manufacturer requirements, up to 99 different stitching patterns can be set in the memory of the machine.

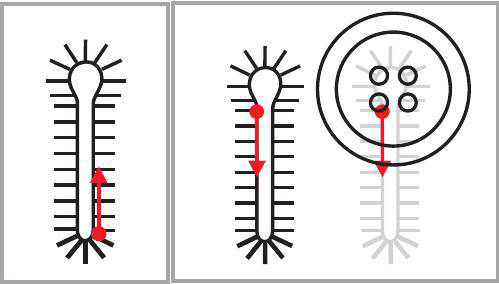

When sewing the round end finish, the operator can set two different start positions, which are either in the first row or in the eye.

When the eye start is selected, the finished buttonhole looks much cleaner since the trimmed thread ends are covered by the button, especially on trouser applications.

Thread Trimming Mechanisms

AF (Adjustable Flybar) Model

AF (Adjustable Flybar) Model recommended for all buttonhole applications that require only

top thread trimming. The size of buttonholes is adjustable from 10 to 50 mm, in increments of 1 mm.

CT (Cord Trim) Model

CT (Cord Trim) Model for use on jeans, trousers or other applications where all threads need to be trimmed from the very end of the buttonhole. Buttonhole sizes ranging from 14 to 35 mm can be sewn by using the two different clamp set.

LTT (Long Tail Trimmer) Model

LTT (Long Tail Trimmer) Model used mostly on tailored clothing, when the end of the buttonhole is left open and the long tails of the threads are pulled through the buttonhole to be tacked in a separate operation. Buttonhole length can be set from 13 to 38 mm. All threads are trimmed with a 20-30 mm tail depending on the buttonhole size.

High Quality & High Productivity

Currently the fastest machine available, running at 2,700 spm

Unbeatable sewing speed adjustable from 1,500 spm to 2,7000 spm directly from the touch screen display. Different sewing speed can be programmed at the start/stop position, around the eye and in the cross bar finish to ensure excellent sewing quality even on difficult materials.

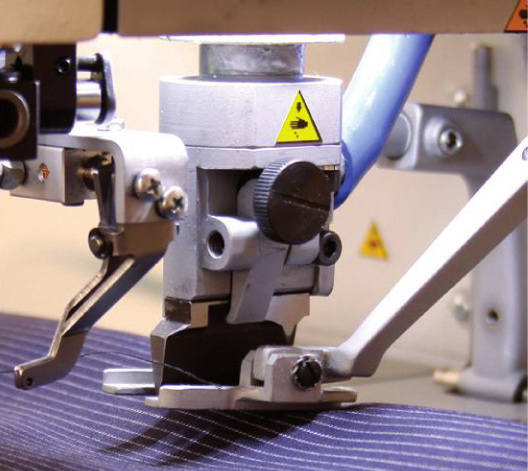

Clean & Reliable Buttonhole Cutting

New vertical cutting system instead of standard lever cutting

The vertical cutting improves the buttonhole cutting in its whole length. The lever cutting system has been replaced by pneumatically controlled vertical cutting mechanism applying the same pressure throughout the buttonhole length and pro- viding the operator with clean and reliable buttonhole cutting on all types and multiple layers of material.

Waste Material Removal and Suction System

The waste material removal & suction system helps to keep the working environment cleaner by removing the cut-off threads and cut-off eye material from the sewing area into a was- te bag. This pneumatically controlled system prolongs the knife lifetime and provides improved buttonhole cutting.

Improves quality & ease of use

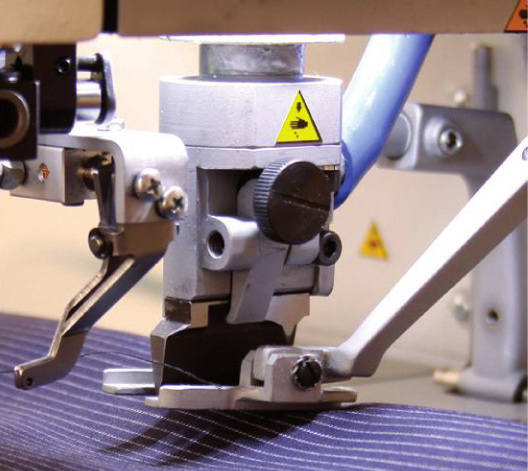

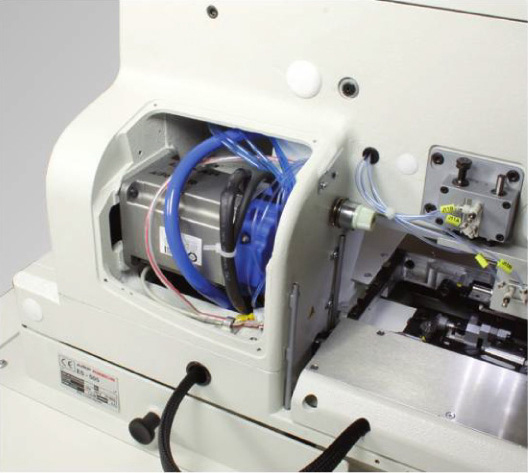

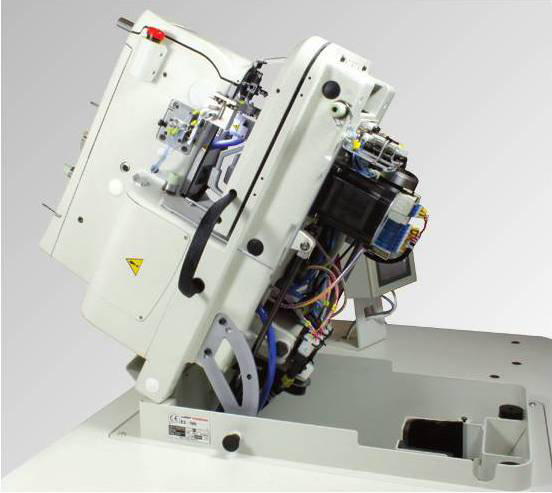

New modular design of the sewing head with integrated sewing motor

The new concept of the sewing head enables sewing in vertical or horizontal direction and provides the operator with larger handling space in the sewing area. The new, stronger main drive increases machine performance and is integrated in the sewing head.

The sewing head can be fixed onto the sewing table or sup- plied as submerged according to the customer’s preference.

New Longer Clamp Feet

The machine is equipped with new longer clamp feet. The longer arms improve the material handling and provide the operator with more space when clamping the sewn garment. Availability of different types of clamp feet for a vari- ety of applications ensures optimum fabric clamping.

Incorporated Round LED Lights

Incorporated LED sewing lights around the cutting block eli- minates darker spots in the sewing area and provides opti- mum light conditions while working on the machine.

New & Improved Mechanisms for Consistent Production

Improved Lubrication System

New design ensures quick and sufficient oil distribution to the critical parts of the machine and redu- ces maintenance time. There are two central oil indicators on the machine.

New patented balancing and sewing drive mechanism

Developed to increase the machine performance, lifetime and decrease the machine vibration.

Optimization of the sewing mechanism

The optimization of the main stitch cam eliminates the machine vibration and reduces the noise level.

Easy Adjustment & Maintenance

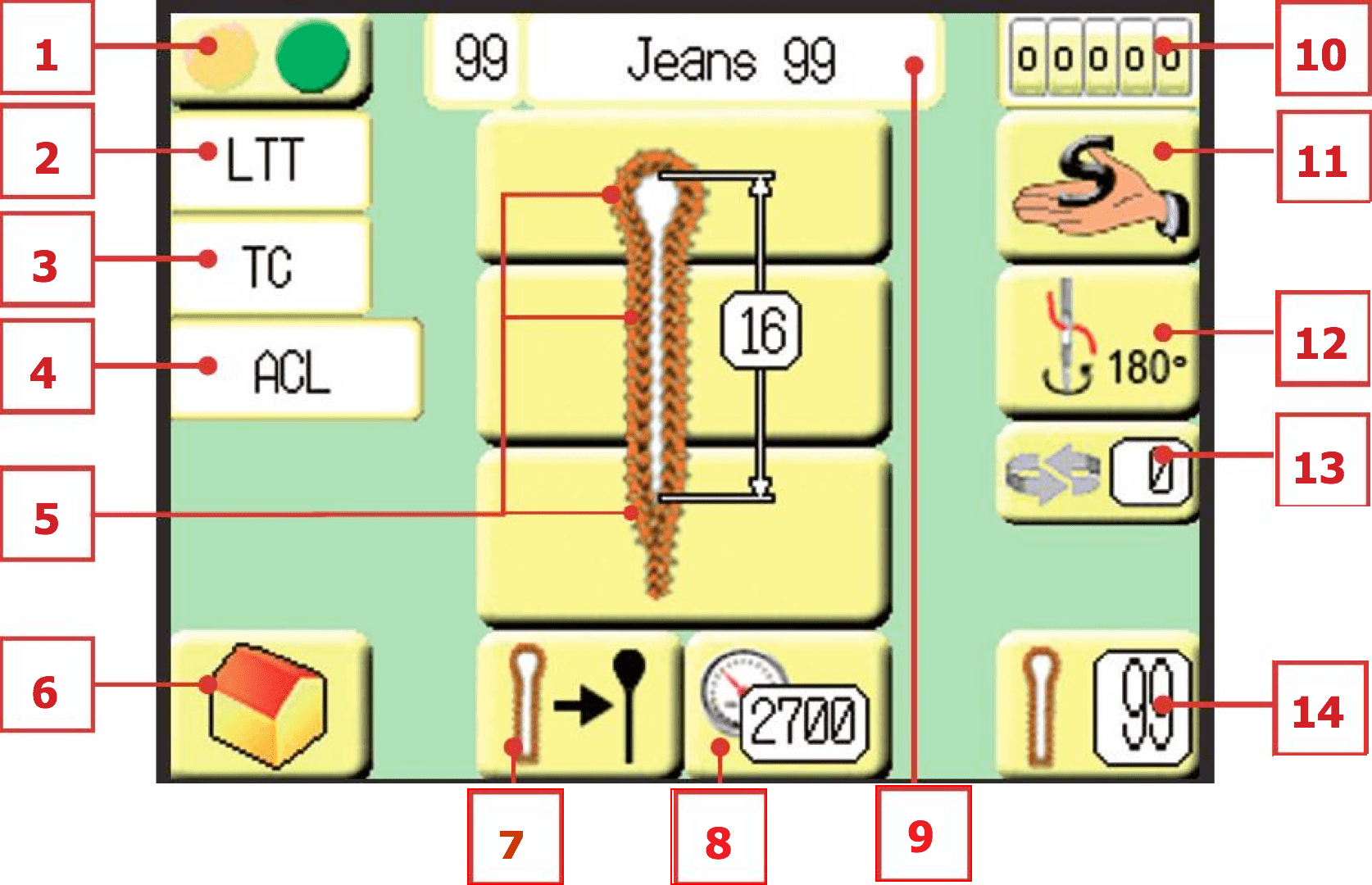

Intuitive Touch Panel Operation

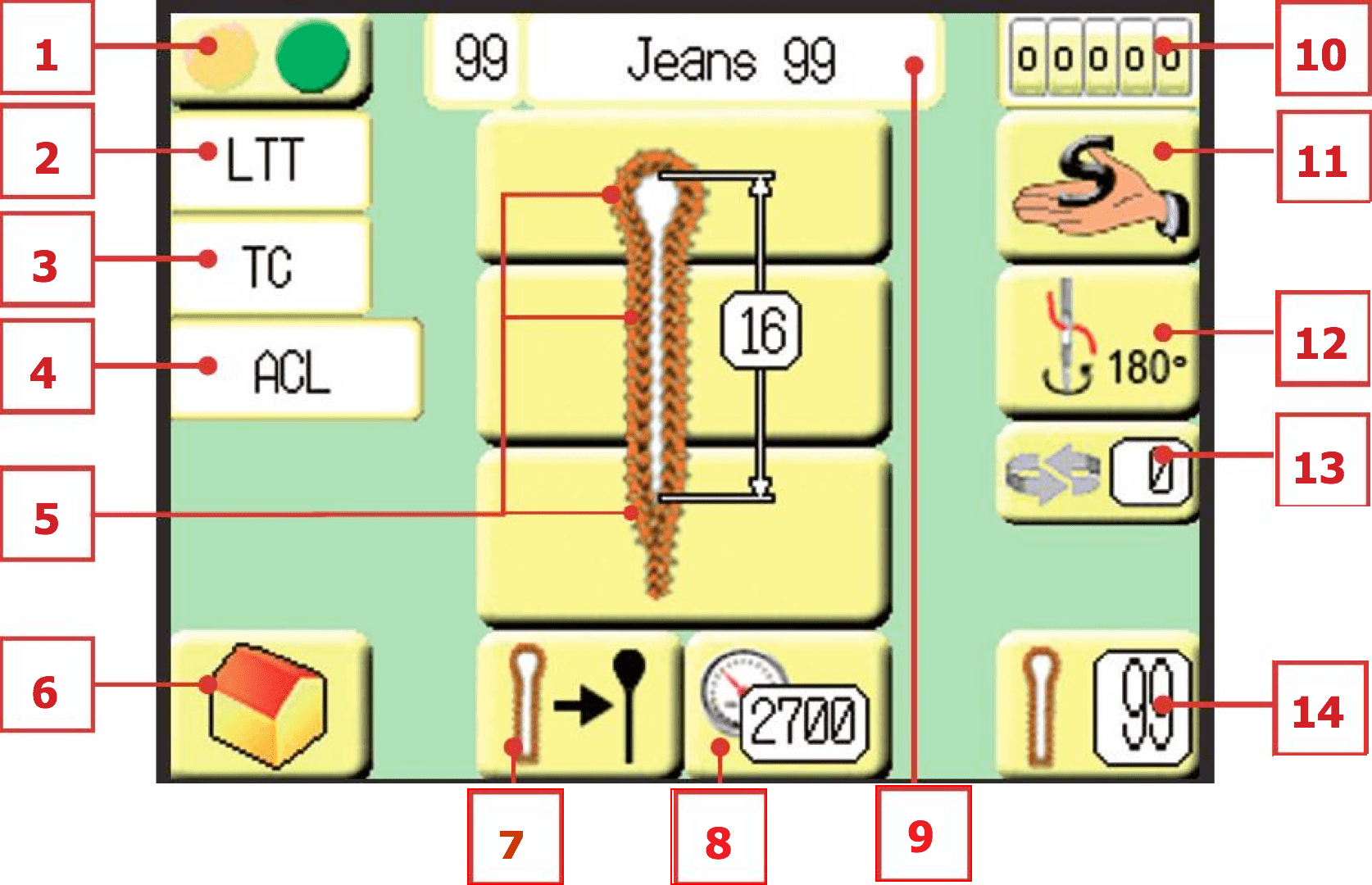

High Resolution Full-Color Touch Screen Display

5.7” LCD high resolution touch screen display is fixed onto the machine table and incorporates new sewing functions. The use of easily understood symbols makes the machine very easy to operate, minimizing training time.

Touch Panel Screen

- Display Machine Status

- Machine Model Modification

- Thread Catcher

- Lapel System

- Buttonhole Setting

- Home Position

- Cutting Selection

- Sewing Speed

- Customized Program Name

- Production Counter

- Service Mode

- Easy Threading Button

- Cycle Mode

- Buttonhole Program Selection

No need of mechanical adjustments when changing the stitch bite

A new technical solution for the stitch bite, including the two basic widths, 1.9 and 2.7 mm, ensures that full stitch bite range is now controlled from the touch screen display only.

Independent thread tension of all threads

The needle, looper and gimp thread tensions can be separately adjusted from the sewing head without the need to til- ting the sewing head. This system improves the sewing quality on different fabrics and therefor the final buttonhole appearance.

Convenient maintenance

The sewing head opening is very easy with the support of a gas spring. The head can be opened in several levels depending on the operator’s needs. Larger machine base also provides better access to adjusting mechanisms.

Features for Automation

Cycle Sewing

The cycle sewing allows up to 21 different buttonhole combinations to be sewn in 47 different programs. The operator can set the machine to sew any of the required buttonhole styles, i.e. to cover all buttonhole applications on a formal jacket. All settings can be done easily by the opera- tor on the touch screen display.

ES-505 Indexer

The ES 505 Indexer machine is specially designed for sewing multiple buttonholes on jacket sleeves and jeans fly fronts at required distances between each buttonhole. The indexer unit ensures that buttonholes are sewn automatically one after another according to parameters set by the operator on the touch screen display.

The new structural design of the indexer unit, placed behind the clamp feet, ensures easy access to the race area if needed.

The indexer unit does not need to be disassembled when taking off the clamp plates in order to change necessary parts.

Available Indexer Models

AFS Model: For jacket sleeves

AFS model is recommended for sewing of regular eyelet buttonholes with single thread, ranging from 10 to 50 mm in length on jacket sleeves.

Model is supplied with thread nipper that holds the top thread at the start of sewing, to ensure that the first stitch is formed properly especially on difficult fabrics.

CTS Model: For jacket sleeves

CTJ Model: For jeans fly fronts

Both models are used for applications with double thread, with or without gimp where all threads are trimmed from the very end of the buttonhole. A buttonhole length of 13 to 35 mm can be sewn with use of different clamp sets.

The CT model for jacket sleeves application is also equipped with the top thread nipper, which especially helps on crossbar buttonhole applications.

| Machine Model | AFS | CTS | CTJ |

|---|---|---|---|

| Applications | jacket sleeve | jeans fly front | |

| Stitch Type | single chainstitch | double chainstitch with or without gimp |

|

| Thread Nipper | Yes | No | |

| Number of Buttonholes | 1 - 6 buttonholes | ||

| Distance between Buttonholes | 8 - 150 mm | ||

| Distance from Fabric Edge (horizontal) | 30 mm | ||

| Distance from Fabric Edge (vertical) | 10 - 80 mm | ||

| Max. Horizontal Feed Amount | 150 mm | ||

日本語

日本語  中文

中文