Texprocess 2024Frankfurt, Germany

- Date

- 23-26 April 2024

- Venue

Messe Frankfurt

Ludwig-Erhard-Anlage 1, 60327 Frankfurt am Main, Germany- Booth

- 9.0 A82

Do Experience Our Premium Technology for Your Premium Profit

Yamato’s practical solutions to various challenges in manufacturing athletic/athleisure wear, casual wear and lingerie, backed by our advanced technology, such as extra stretch seam, which adds extra value on your functional garments, deskilled operation for uniform high-quality finish without relying on skilled operators, and even possibility to skip operation.

Please come and experience Yamato's latest solutions that solve various problems in apparel manufacturing.

Highlight

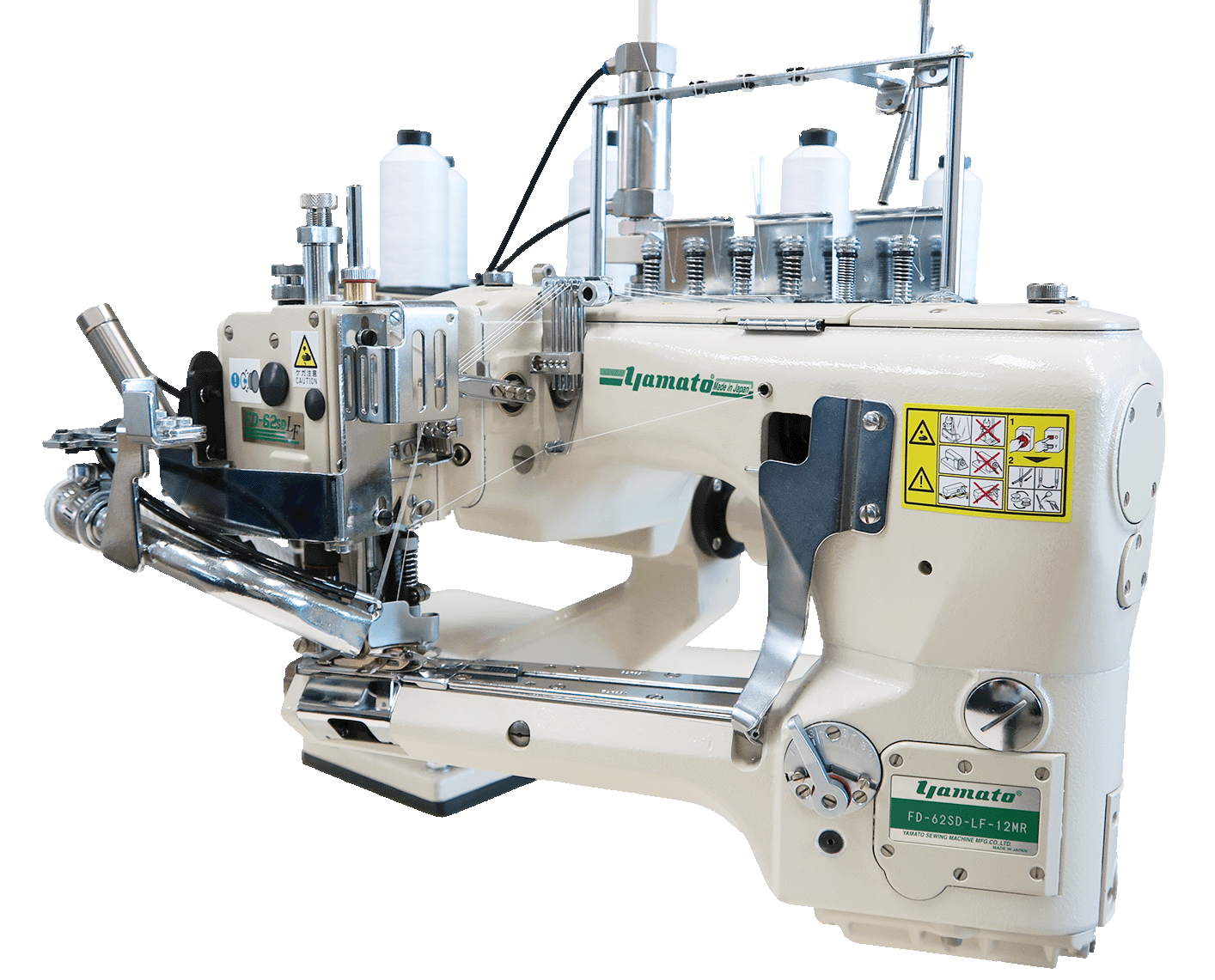

FD-62SD-LF: The flatseamer designed for stretch materials

Reduces defects and achieves extra stretch, outstanding appearance, comfort & functionality

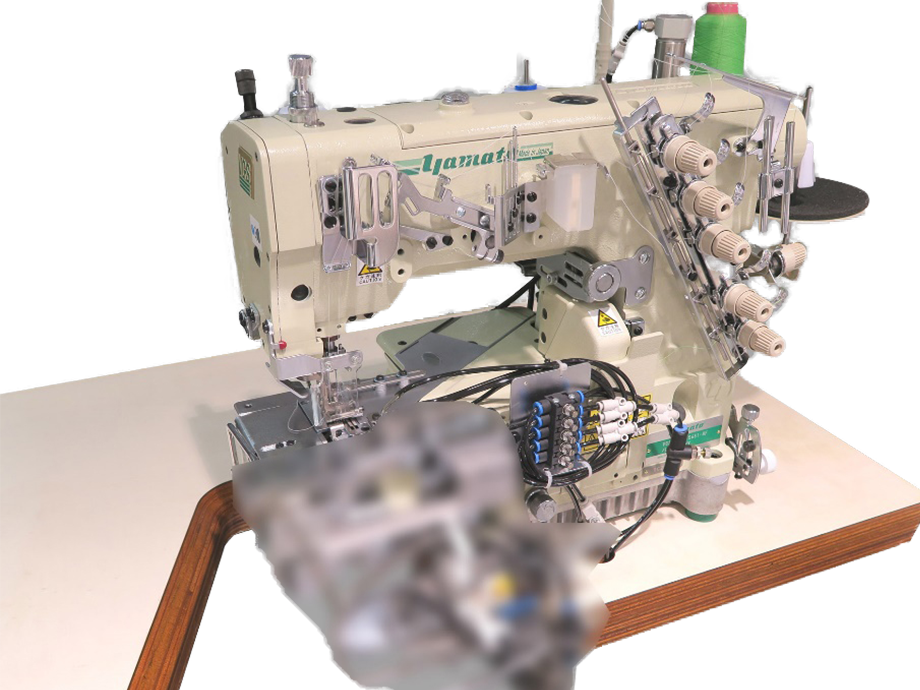

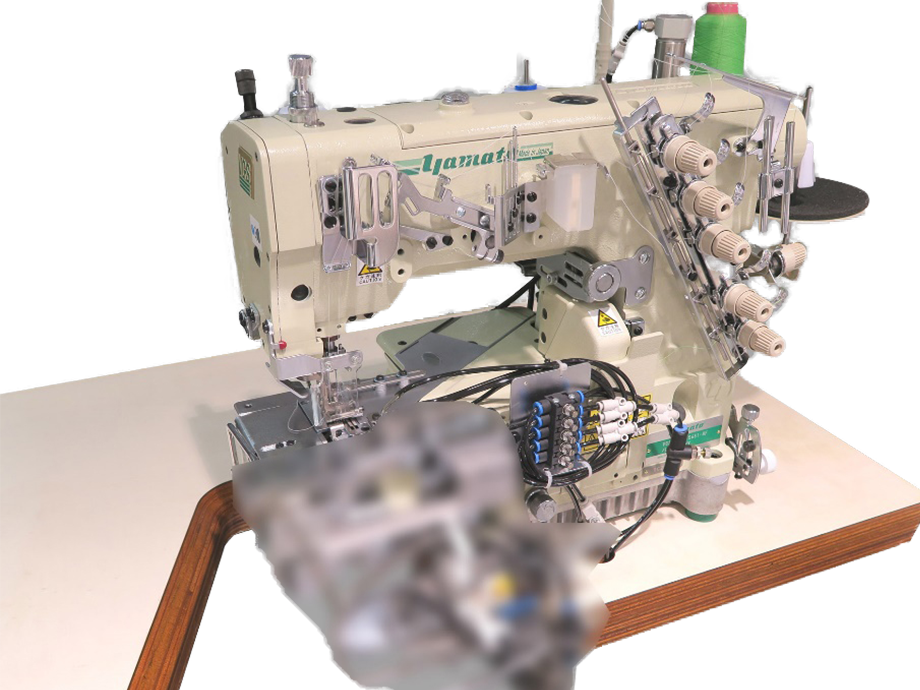

EZH-B significantly deskilizes the hemming operation

Circular hemming, one of the most critical operations on knitwear assembly has been much deskilled now

UTQ eliminates bar-tacking process

UTQ enables you to eliminate tacking process thanks to the unique anti-unraveling technology to avoid seam unravelling from the end.

Active Thread Control enables you to achieve more stretch

Yamato's signature Active Thread Control Technology supports ideal seam over wide range from soft and elastic seams for microfibers to tight seams for outer wears.

Premium Stitch Quality + Profitable Automation

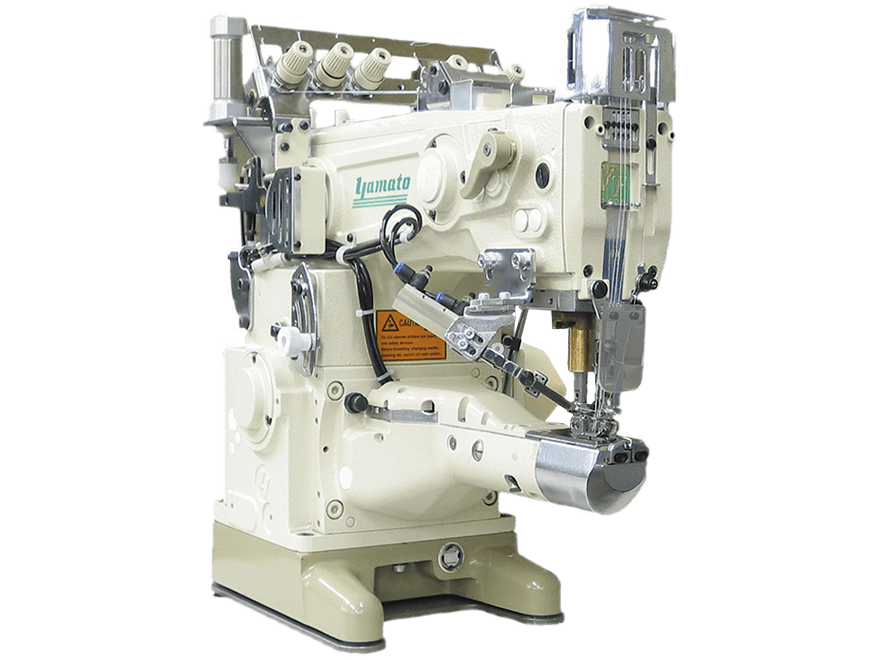

EZH-B-VGS3721SD/UTQ

Semi-Automatic Easy Bottom Hemming Workstation with Anti-Unraveling Device

Circular hemming, one of the most critical operations on knitwear assembly has been much deskilled now

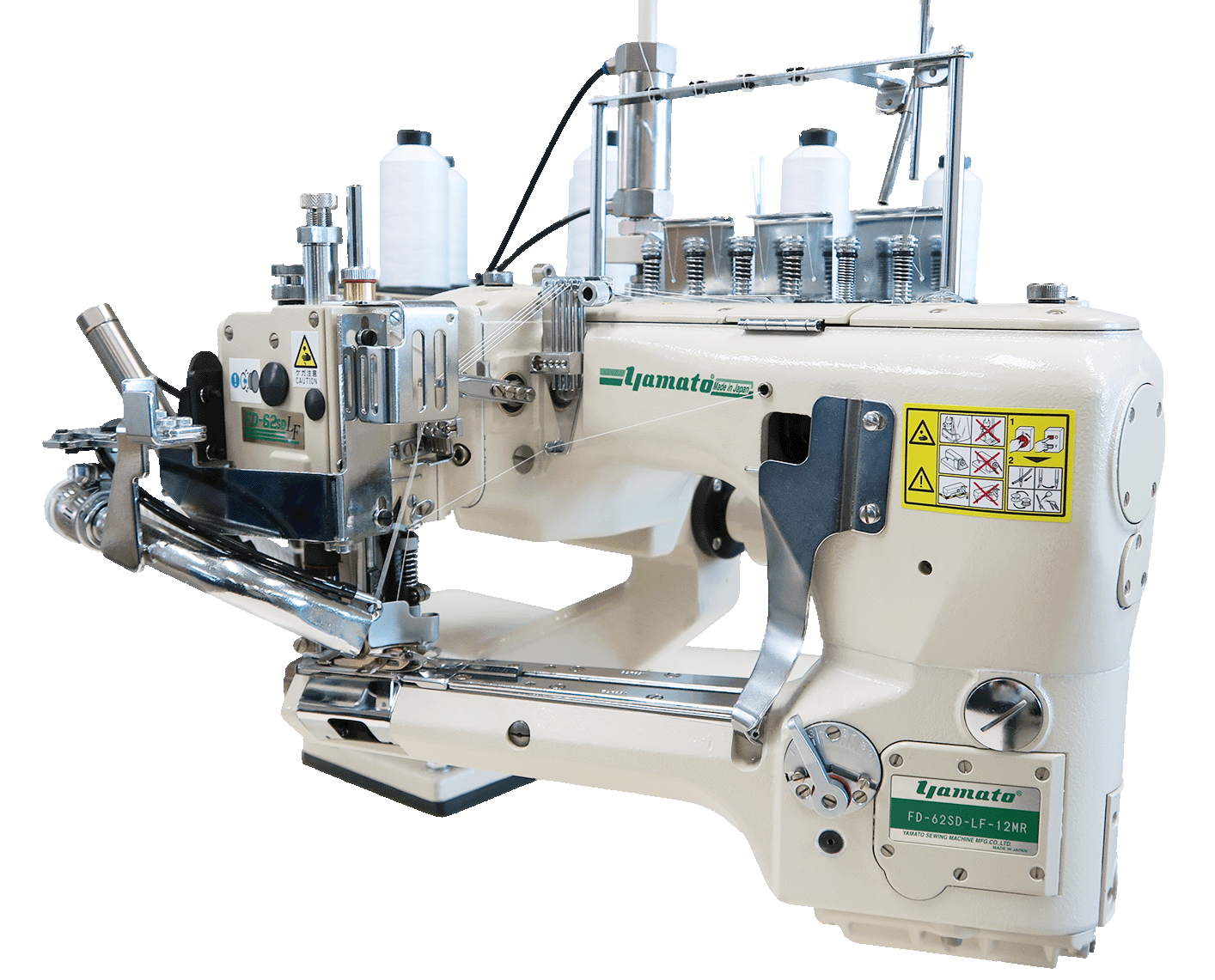

FD-62SD-LF

4 Needle 6 Thread, Feed-off-the-arm "Loss-Free" Flatseamer

The Flatseamer for stretch materials that reduces defects and achieves extra stretch, outstanding apperance, comfort & functionality

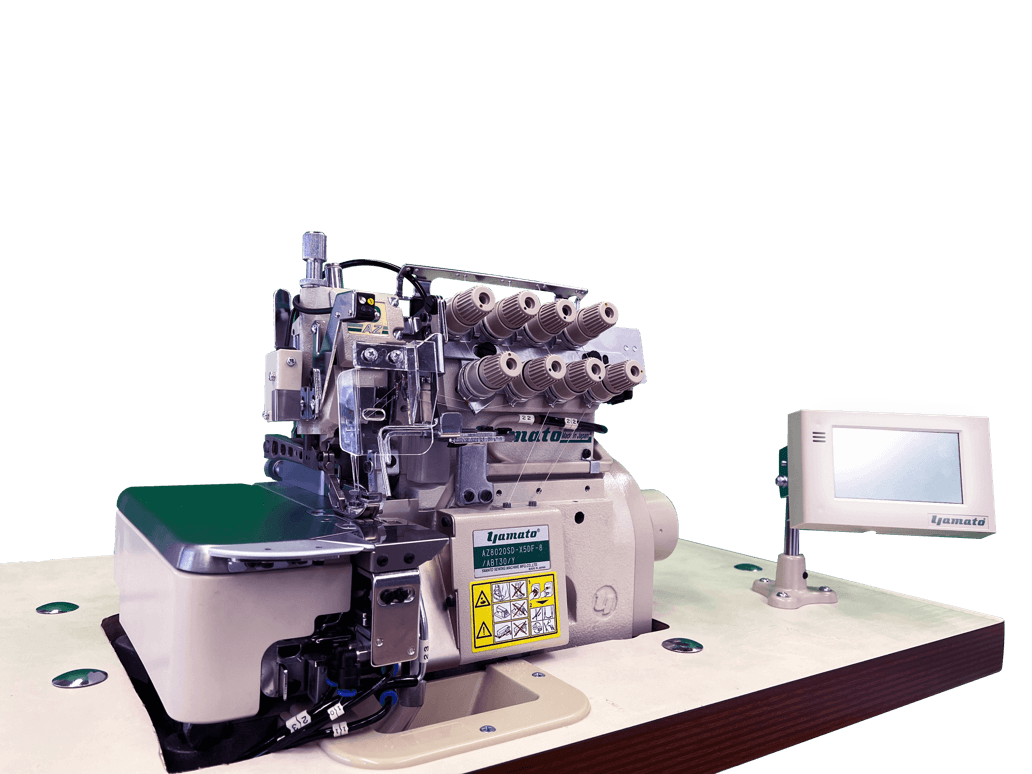

AZ8020SD/ABT30

2 Needle 4 Thread "Speed & Dry" Overlock Machine for General Seaming with Automatic Back-tacker

ABT30 enables real quick back-tack procedure for you to operate like usual overlock with chain cutter only. You can reduce a post-sewing process.

CM-364/AT/TS2/TF

1 Needle 1 Thread Chain Stitch Blind Stitch Machine with Differential Feed and Skip Stitch Mechanism

No need to bind the seam end by hand. High productivity Blind Stitch Machine

Unique Standard Machines

Z7020SD-Y5DF/K2/SC18/SAS

Economy Type 2 Needle 4 Thread "Speed & Dry" Overlock Machine for General Seaming

Speed + Dry finish overlock machine with the ideal stitch performance and the device that saves thread & energy consumption

VT2513-156M-34K/UT-A34/ST2-A/Y

3(2) Needle 5(4) Thread Feed-up-the-arm Interlock Stitch Machine for Covering

From thin to thick fabrics:

Yamato’s Multi-purpose Interlock stitch machine

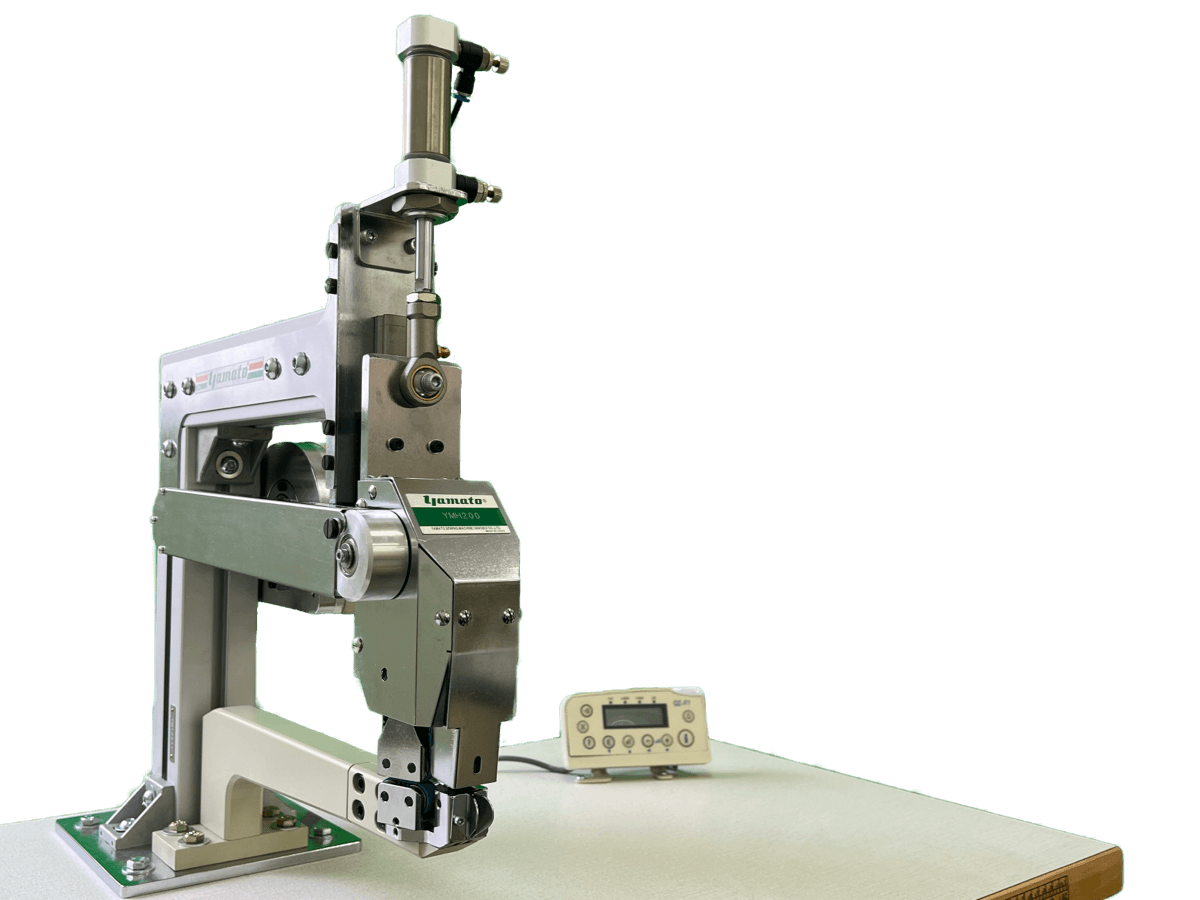

YMH-200

Seam opening machine

Mechanize the seam opening process, improving efficiency by more than 50% compared to manual operation, and eliminating the risk of variation and staining caused by manual operation.

Real-time Production Monitoring

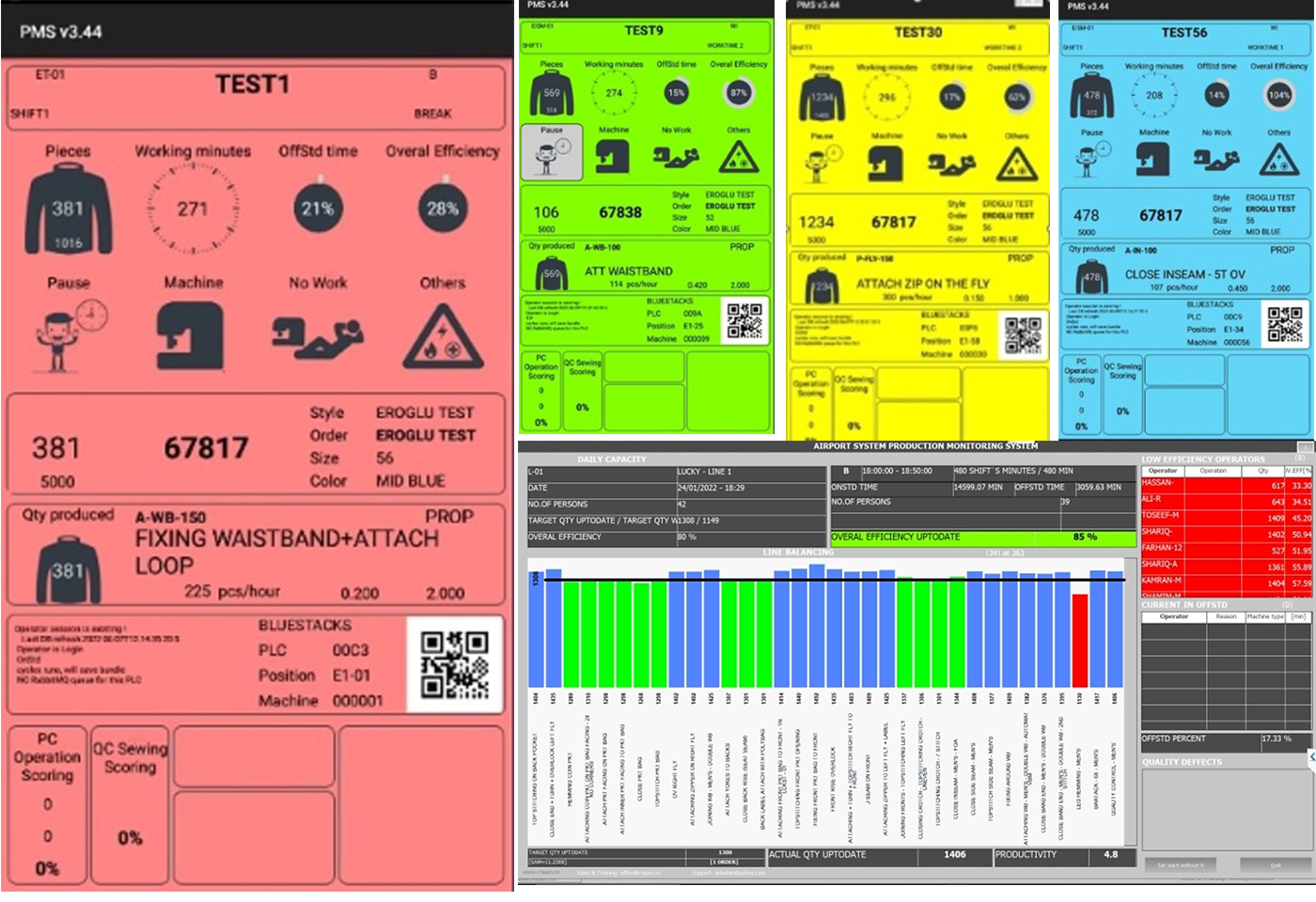

PMS

Production Management System

Real-time production monitoring allows production bottlenecks to be identified and quickly resolved.

Data can be collected from all types of sewing machines and requires no extra work by the operator.

Supervisors and managers as well as operators are motivated to achieve their goals.

Various optional systems are available for quality assurance, machine maintenance, etc.

Information

- Texprocess 2024

- Date:

- April 23 - April 26, 2024

(Tuesday - Friday) - Venue:

- Messe Frankfurt

Ludwig-Erhard-Anlage 1, 60327 Frankfurt am Main, Germany - Booth:

- 9.0 A82

日本語

日本語  中文

中文