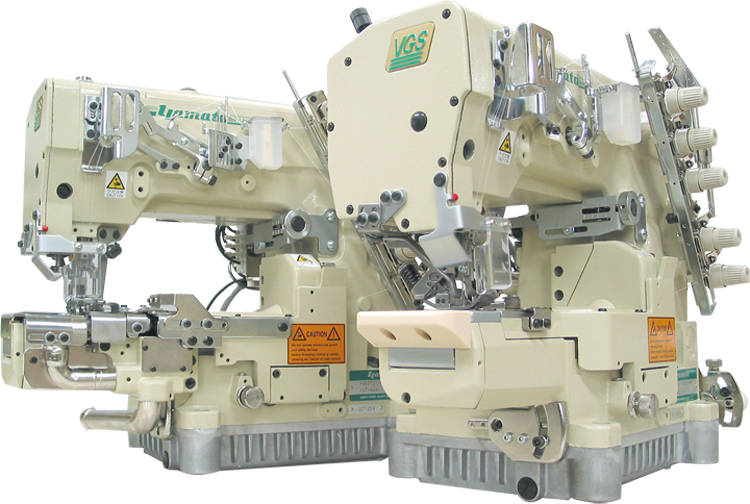

Cylinder Bed Interlock Stitch Machine with Top FeederVGS-8 series

Cylinder Bed Interlock Stitch Machine with Top Feeder releases you from headaches on troubles possibly occur in your sewing factory

- Rear Pivot Top Feed Dog eliminates sewing slippage, twisting and distortion of any kinds of fabric.

- Yamato's signature Active Thread Control supports ideal seam over wide range from soft and elastic seams for microfibers to tight seams for outer wears.

- Yamato "Non-stain" Technology for minimizing the risk of oil stain, the most frequent cause of defects.

Dealing with wide variety of items and styles, Yamato VGS will release your headache on troubles possibly occur in your sewing factory.

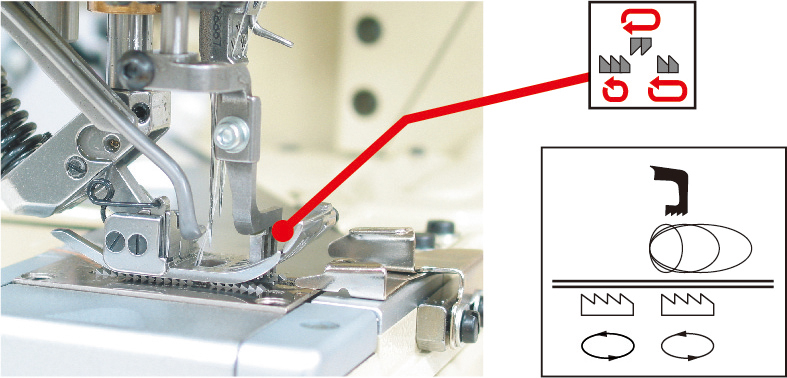

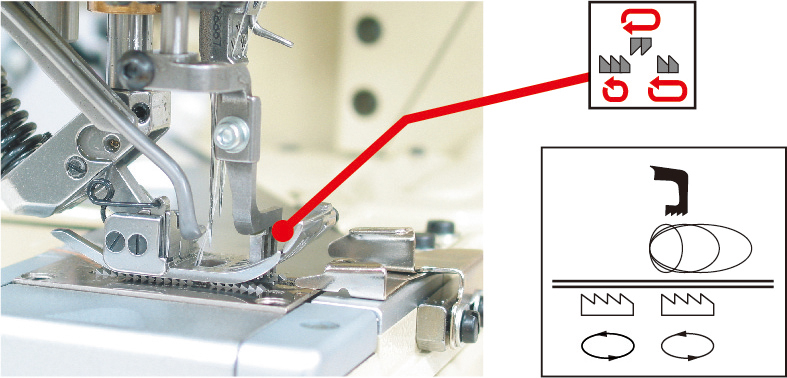

Stable Finish with the Rear Pivot Top-Feed Mechanism

Rear Pivot Top Feed Dog eliminates sewing slippage, twisting and distortion of any kinds of fabric.

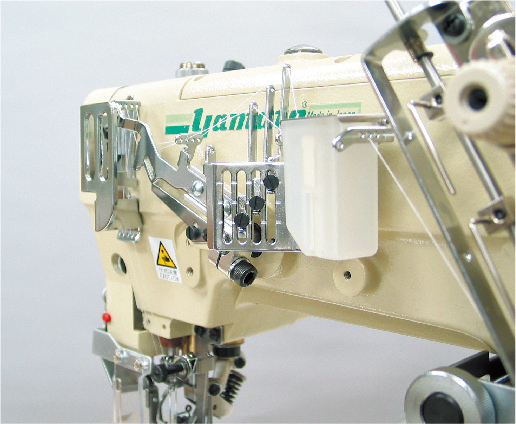

Yamato's signature Active Thread Control Technology

Active Thread Control supports ideal seam over wide range from soft and elastic seams for microfibers to tight seams for outer wears.

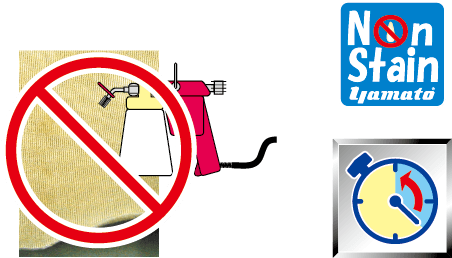

Yamato "Non-Stain" Technology

Yamato "Non-stain" Technology minimizes the risk of oil stain, the most frequent cause of defects.

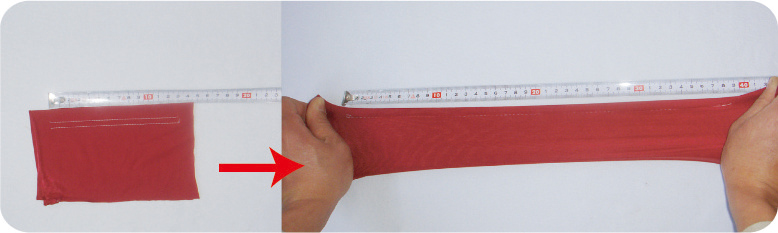

Stable Finish with the Rear Pivot Top-Feed Mechanism

Rear Pivot Top Feed Dog eliminates sewing slippage, twisting and distortion of any kinds of fabric.

Top Feed Dog always bring top ply of fabric closer to needle drop point at any feed amount. This is because the movement of Yamato Top Feed Dog is rear pivot.

Top Feed Dog eliminates sewing slippage, twisting and distortion of any kinds of fabric.

Also, Top Feed Dog and Feed Dog Adopter is set at flat faces for easier height adjustment according to thickness of fabric.

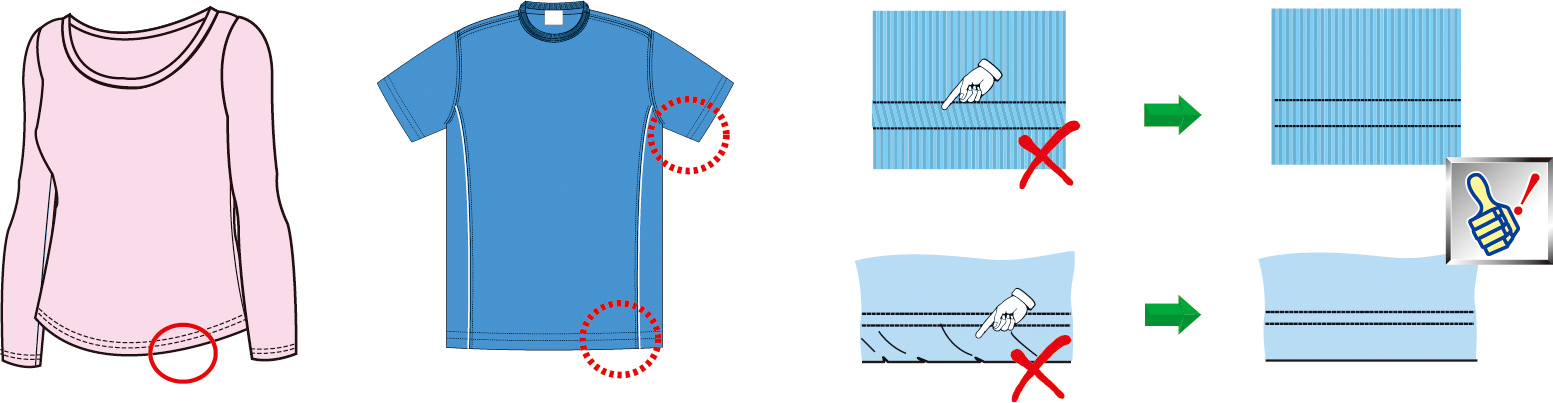

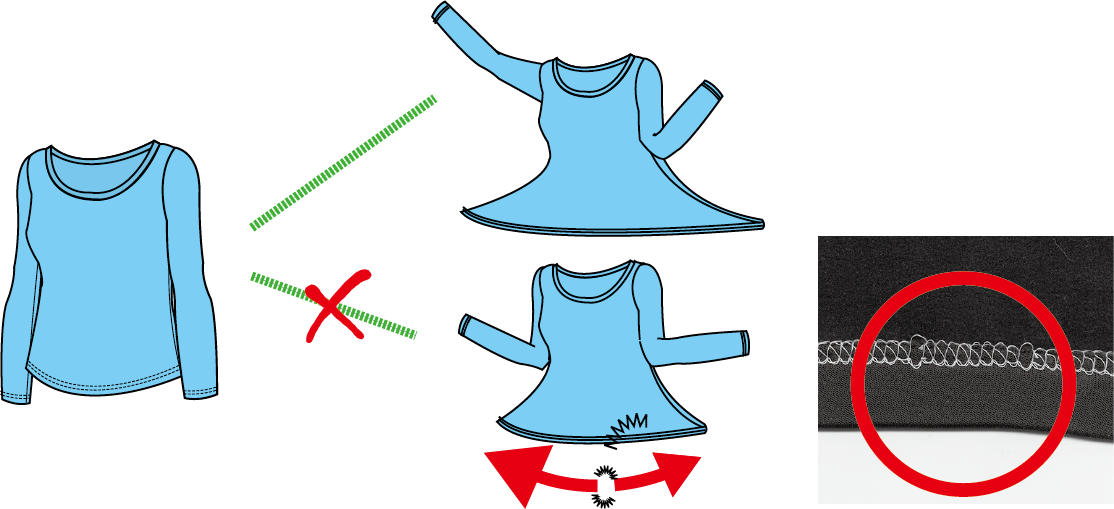

Suitable for microfibers. Active Thread Control supports ideal seam over wide range from soft and elastic seams for microfibers to tight seams for outer wears

Epoch-making soft and elastic seams suitable for microfibers

If you are looking at further flexibility for the recent frequent and big change in sewing condition, Yamato's signature "Active Thread Control" is the right technology.

Active Thread Control performs epoch-making soft and elastic seams suitable for garments with lightweight, soft and stretchable microfibers, such as athletic wears or ladies' intimates.

Unlike the conventional way of thread control, which mainly use tension (resistance) on each thread, Yamato "Active Thread Control" takes in and draws back thread when it is required, and well-balanced seams with minimum necessary tension(resistance) for thread regulation.

The soft and elastic seams made with Active Thread Control offer the tunnel free finish preventing seam breakage.

Tunnel Free Finish, Comfortable to Wear

200% plus stretch!

High streatch seaming prevents seam breakage.

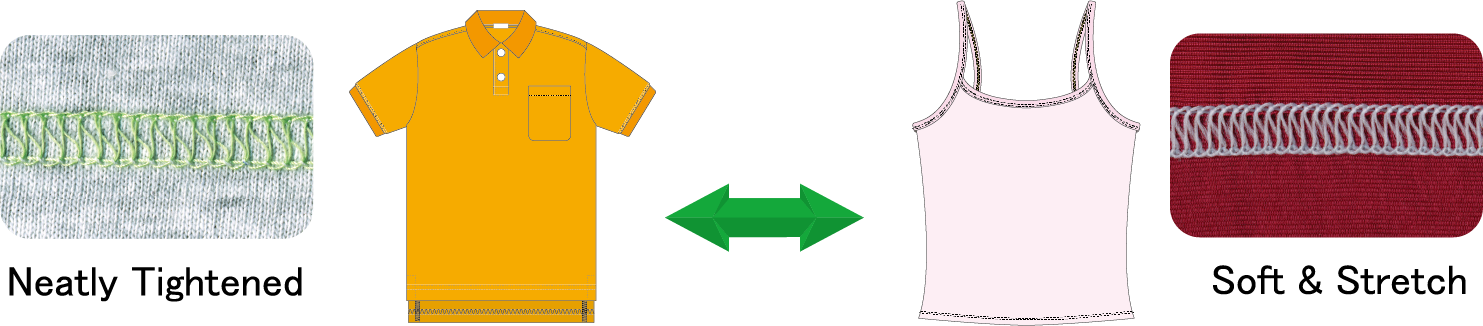

Ideal seam over wide range from soft and elastic seams for microfibers to tight seams for outer wears

Making ideal seams over wide range, Active Thread Control supports wide variety seams from soft and elastic seams to tight seams. Yamato Active Thread Control makes ideal thread balance control to form any desiered seam, with less stress given to each thread.

Adjustment from soft to tight seam can be done simply and visibly, addressing frequent changes of sewing conditions.

Wide variety of seams can be performed with Active Thread Control, by the simple and "visible" adjustment, not by the "fuzzy" adjustment tension devices.

Adjustment from soft to tight seam can be done simply and visibly to minimize required skills and downtime spent for addressing frequent changes of sewing conditions.

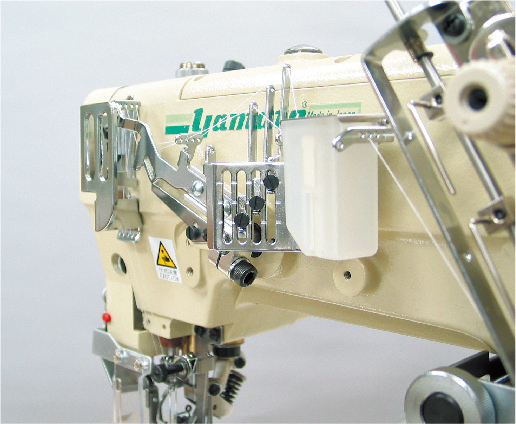

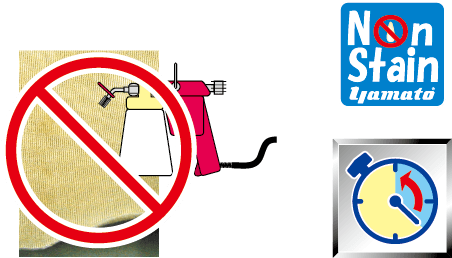

Yamato "Non-Stain" Technology

Yamato "Non-stain" Technology for minimizing the risk of oil stain, the most frequent cause of defects.

Yamato's "Non-stain" technology will not sacrifice the performance and the durability of machines, but keep the machine running smoothly at high speed for long life.

While giving enough lubrication for the internal driving mechanism, Yamato exclusive sealing sytem prevents the oil from coming to the sewing area through moving parts. This feature minimizes the risk of oil stain, one of the most frequent cause of defects.

Non-stain finish minimizes your loss, such as downtime and extra cost caused by spot removing operations.

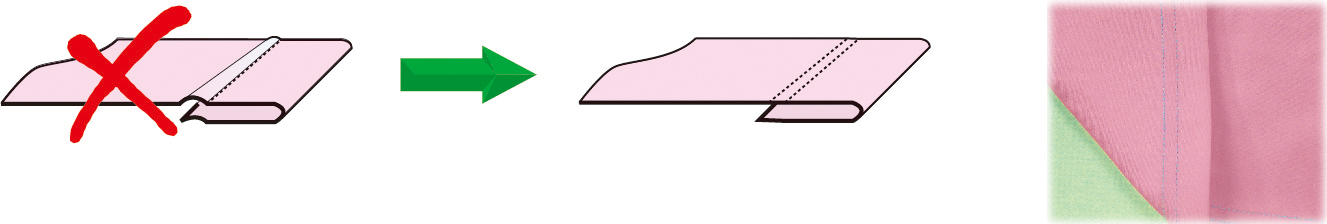

Easier Handling

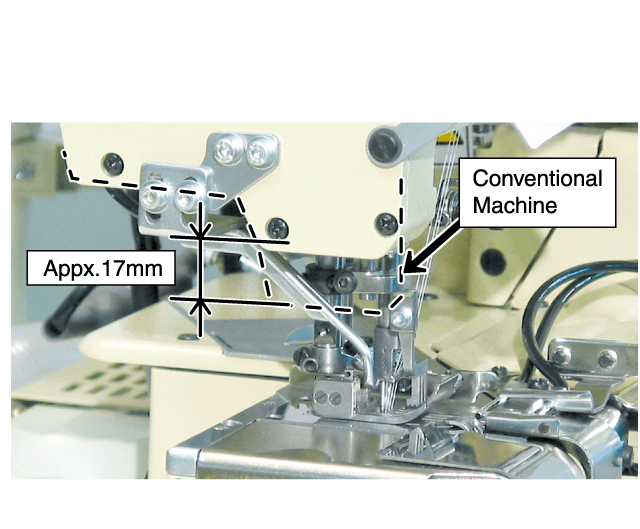

The position of needle bar driving link is designedhigher by 17 mm than conventional machines to keep more space at the left side of needle drop point. This helps you for easier handling.

日本語

日本語  中文

中文